Top Suppliers Bolt Hole Casters - ED4 Series-Threaded stem type – GLOBE

Top Suppliers Bolt Hole Casters - ED4 Series-Threaded stem type – GLOBE Detail:

High-class PU caster

Super muting PU caster

Super PU caster caster

High-strength artificial rubber caster

Conductive artificial rubber caster

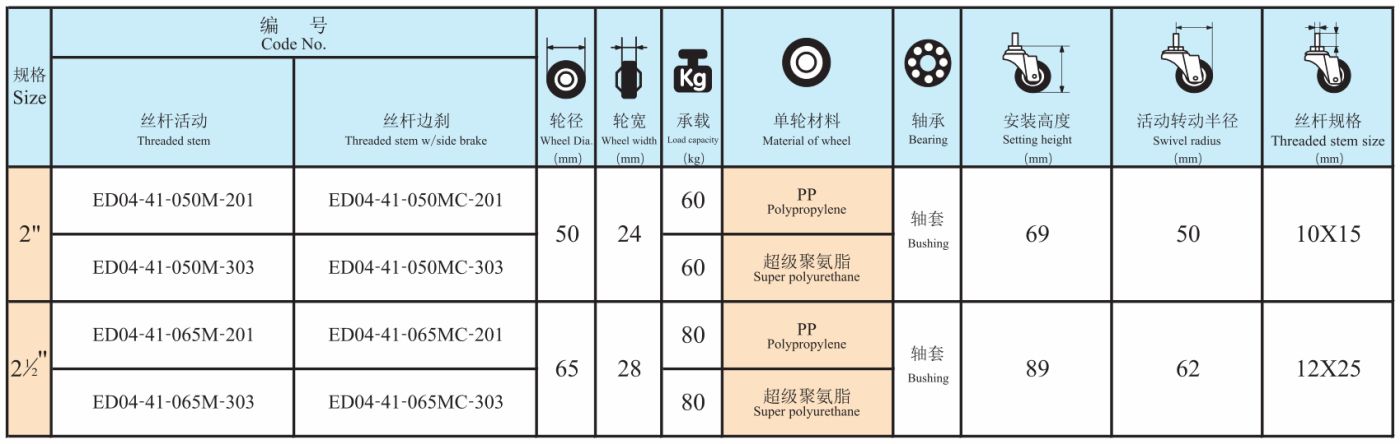

Product Parameters

|

Size |

Code No. |

Wheel Dia. (mm) |

IWheel width (mm) |

Load capacity (kg) |

Material of wheel |

Bearing |

Setting height (mm) |

Swivel radius (mm) |

Threaded stem size (mm) |

|

|

Threaded stem |

Threaded stem w/side brake |

|||||||||

|

2n |

ED04-41-050M-201 |

ED04-41-050MC-201 |

50 |

24 |

60 |

PP Polypropylene |

|

69 |

50 |

10X15 |

|

ED04-41-050M-303 |

ED04-41-050MC-303 |

60 |

Super polyurethane |

Bushing |

||||||

|

2X” |

ED04-41-065M-201 |

ED04-41-065MC-201 |

65 |

28 |

80 |

PP Polypropylene |

|

89 |

62 |

12X25 |

|

ED04-41-065M-303 |

ED04-41-065MC-303 |

80 |

Super polyurethane |

Bushing |

||||||

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

Contents and methods of detection of blue and black parts

1. The color of the air oxide film: the color should be even after bluish, and no stains and part of the air oxide film are not allowed. Because of the different surface smoothness of the same part, or parts with partial heat treatment or electric welding position, the color difference is allowed. After the carbon steel and high-alloy steel parts turn blue, there should be a symmetrical black air oxide film. Castings and silicon-containing carbon steel parts are allowed to be yellowish brown or dark brown after turning blue.

2. Compressive strength of air oxide film: The air oxide film and the main fusion compressive strength, rub hard with a dry cloth, and do not show the metal texture.

3. The tightness of the air oxide film: When the parts become blue, use 3% sodium thiosulfate solution to corrode for about 30 seconds before applying oil, and no copper electroplating is allowed on the surface of the parts. However, a small amount of copper plating stains can occur on sharp edges, corners and welding positions.

4. Anti-corrosion of air oxide film: corroded by 3% edible salt solution for 3 hours without corrosion.

5. The smoothness of the parts and it: After bluing cleaning, drop 1-2 drops of phenolphthalein alcohol solution on the product piece. For example, the phenolphthalein alcohol solution is pale pink, indicating that the cleaning is not clean.

Product detail pictures:

Related Product Guide:

We provide good power in high-quality and progress,merchandising,revenue and internet marketing and operation for Top Suppliers Bolt Hole Casters - ED4 Series-Threaded stem type – GLOBE , The product will supply to all over the world, such as: Denmark, Ethiopia, Serbia, We always insist on the principle of "Quality and service are the life of the product". Till now, our products have been exported to more than 20 countries under our strict quality control and high level service.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.