Globe caster has almost 30 years of experience in the production of casters and we provide customization service for the production of specialized caster products. We have undertaken a series of caster projects regarding consulting, design, processing, and after-sales services.

Why choose us?

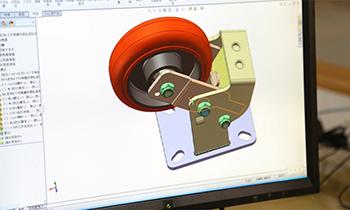

We often develop our own molds and employ large-scale processing equipment to meet the mass production of casters. Our product design team is one of our biggest assets when it comes to meeting customer needs. We have been producing hundreds of customized casters for various customers. These custom casters are necessary for non-standard applications, particularly those with highly specific requirements.

How to customize?

● Type of casters selection

1. Weighing range: 10kg – 2 tons, even heavier

2. Surface material: nylon, polyurethane, polypropylene, rubber, synthetic rubber, cast iron

3. Color: red, black, blue, grey, orange, transparent, green.

4. Single wheel or double wheel design

● Surface treatment process

In order to enhance the serviceability of our products and extend their life span, these surface treatments can be applied to our casters: blue zinc plated, color zinc plated, yellow zinc plated, chrome plated, baked black paint, baked green paint, baked blue paint, electrophoresis.

● Braking method selection

Moving, fixed, moving brakes, fixed brakes, side brakes, double brakes

● Ambient temperature range: -30 ℃ to 230 ℃

Customization process

1. Customers provide drawings, R&D Management studies the drawings to see if we have similar products.

2. Customers provide samples, we do technical analysis of the structure and draw drawings.

3. Account mold costs, quotes, proceed mold production.

Post time: Dec-16-2021