Short Lead Time for Machinery Caster - EF9 Series-Top plate type-Swivel/Rigid(Flat)(Chrome-plating) – GLOBE

Short Lead Time for Machinery Caster - EF9 Series-Top plate type-Swivel/Rigid(Flat)(Chrome-plating) – GLOBE Detail:

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

What kind of caster is more suitable for the application of aluminum alloy profile steel pipe scaffolding?

Aluminum alloy profile steel tube scaffolding is also called mobile quick-installed aluminum profile steel tube scaffolding, and it happens to be able to assist the aluminum alloy profile steel tube scaffold to move quickly because of the casters. However, in practical applications, if the wrong caster is selected, it will cause a lot of trouble for the application. What kind of caster is more suitable for the application of aluminum alloy profile steel pipe scaffolding?

1. The key is better. Generally, the aluminum alloy profile steel pipe scaffold itself is not too heavy, but if there are objects on it, the net weight of all the iron frames will increase, and the load of the casters also seems very critical. Generally, the load capacity of casters up to 720KG can basically reach the full load capacity of all aluminum alloy profile steel pipe scaffolding.

2. Do not use iron parts as much as possible. Because of the conditions of the construction site, water storage sometimes occurs, or the aluminum alloy profile steel pipe scaffolding touches water due to the temperature, but the aluminum alloy profile steel pipe scaffold itself is the aluminum alloy profile material, and it will not be affected by water. But if the caster has an iron part, it will definitely be harmed.

3. Casters with double pedal structure. There are generally two designs for locking and unlocking casters: single-pedal and double-pedal. The difference between them depends on whether the single-pedal pedal is stepped on or locked. When the pedal must be turned on and moved, it needs to be lifted up. It is very laborious to apply it, and it is more difficult to handle it after a long time. . There is no such problem with the double-pedal structure. He has pedaling parts on both sides of the casters. Stepping on one side will brake and lock, and step on the other side to open it without using a portable pull. And the double-pedal structure has a load of 720KG, while the single-pedal structure is generally only 300-600KG.

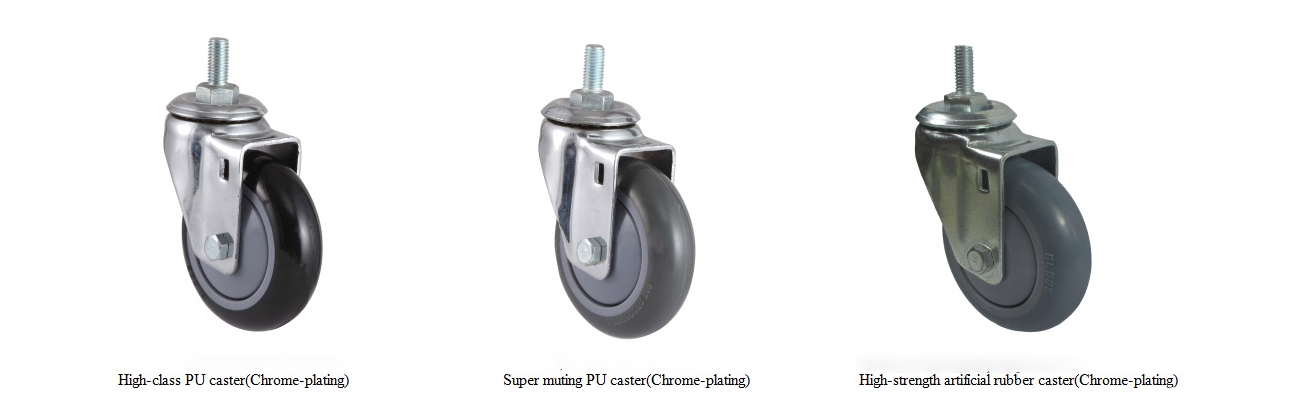

Product detail pictures:

Related Product Guide:

Our progress depends about the advanced products ,fantastic talents and continuously strengthened technology forces for Short Lead Time for Machinery Caster - EF9 Series-Top plate type-Swivel/Rigid(Flat)(Chrome-plating) – GLOBE , The product will supply to all over the world, such as: Lebanon, Italy, Mauritius, To win customers' confidence, Best Source has set up a strong sales and after-sales team to deliver the best product and service. Best Source abides by the idea of "Grow with customer" and philosophy of "Customer-oriented" to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let's grow together!

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.