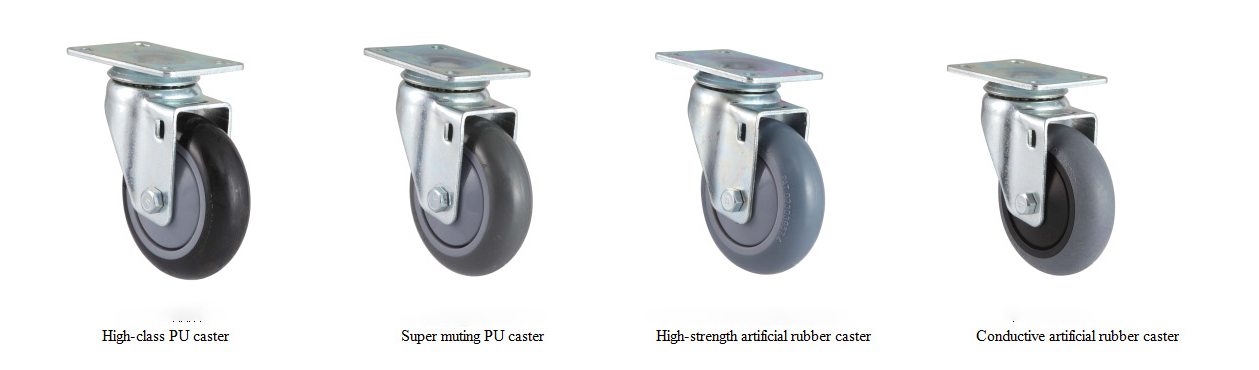

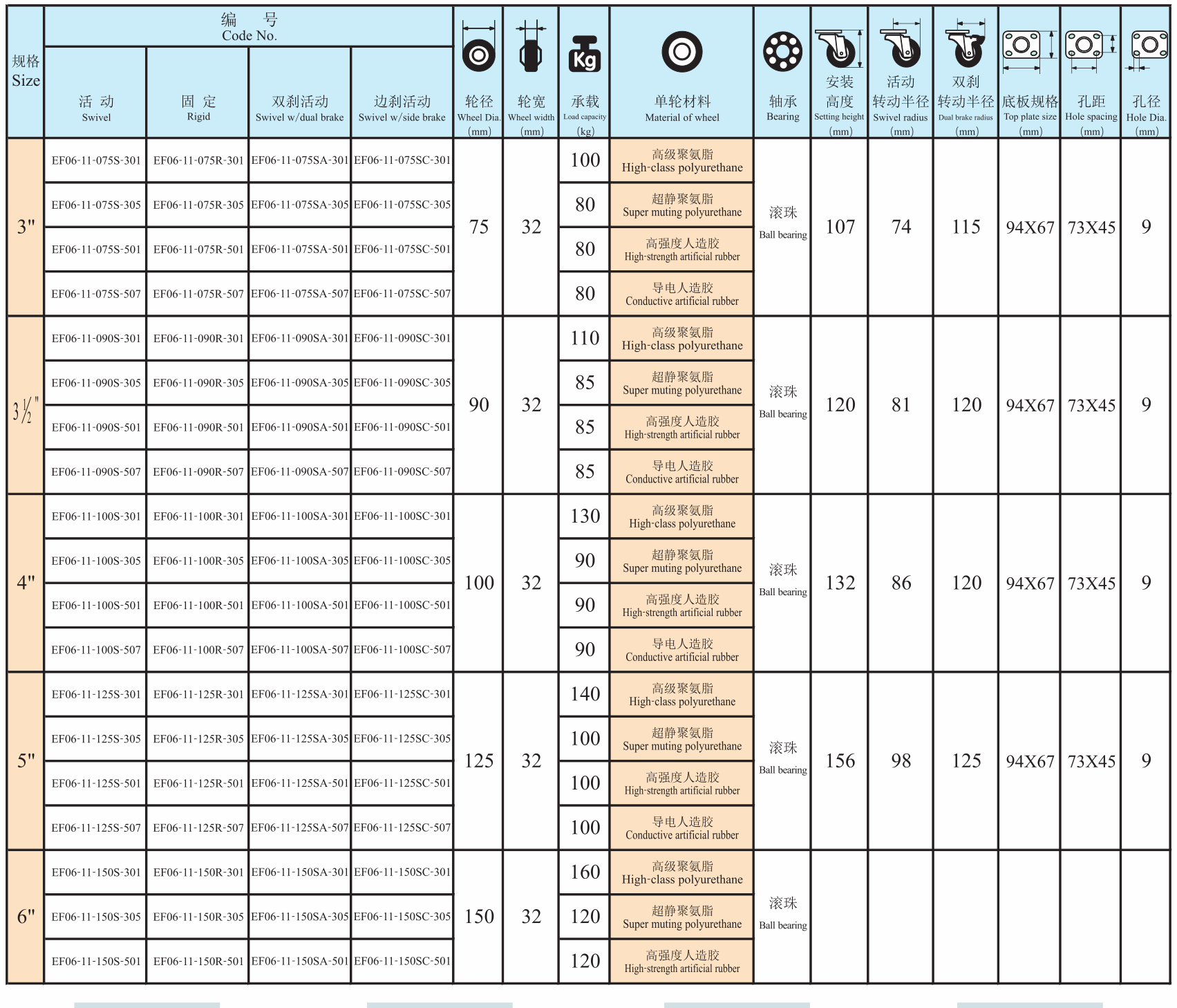

Reasonable price for Tpr Wheel - EF6 Series Top plate type-Swivel/Rigid(Round)(Zinc-plating) – GLOBE

Reasonable price for Tpr Wheel - EF6 Series Top plate type-Swivel/Rigid(Round)(Zinc-plating) – GLOBE Detail:

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

Features of heavy duty casters

1. Heavy-duty casters have large volume and heavy load.

2. The support material is thicker, and the parts are mainly stamped and welded.

3. The grinding wheel is mainly made of cast iron inner core grinding wheel, which is firm, without deformation and rebound.

4. Suitable for complex indoor and outdoor environments, and also suitable for heavy objects handling and handling.

5. Equipped with oil injection port, lubrication and stability during use.

Industrial casters arrangement and operating sensitivity

Due to different requirements for flexibility and controllability of instruments and machines, industrial casters must be positioned and arranged accordingly.

1. Arrangement of three universal casters with the same structural height

Suitable for low load and narrow aisles. The transport equipment can move freely in all directions. When traveling straight, transporting equipment is only relatively difficult to guide. This can be improved by installing a directional brake on one of the three swivel casters. This type of caster arrangement may cause the transportation equipment to tip over, resulting in poor tipping stability.

2. Arrangement of four universal casters with the same structural height

Suitable for narrow aisles. The transport equipment can move freely in all directions. When traveling straight, transporting equipment is only relatively difficult to guide. This can be improved by installing directional brakes on the two universal casters, and the moving performance is good.

3. Arrangement of two universal casters and directional casters with the same structural height

The most commonly used caster arrangement, suitable for traction operations. The transport equipment can be well guided when going straight and turning. It is relatively difficult to move equipment in a narrow aisle.

If you don’t use directional casters, you can also use two single wheels on one shaft, so that the load-bearing capacity of the arrangement is enhanced, and the overturning stability is enhanced.

4. Four directional casters, the middle directional caster has a slightly higher structural height arrangement

Practical caster arrangement. The transport equipment can be well guided when traveling straight. By distributing the load on the intermediate directional casters, the transport equipment can be controlled and rotated at a fixed point relatively easily. In this caster arrangement, the transport equipment may overturn and shake.

If you don’t use the directional caster in the middle, you can also use two single wheels on one shaft. The guiding function is enhanced when this arrangement goes straight.

5. Two swivel casters and directional casters, of which the directional casters have a slightly higher structural height arrangement

Suitable for traction operations. The transport equipment can be well guided when going straight and turning, and it is easy to turn at a fixed point. In this caster arrangement, the transport equipment may overturn and shake.

If you don’t use the directional caster in the middle, you can also use two single wheels on one shaft. The guiding function is enhanced when this arrangement goes straight.

6. Arrangement of four universal casters and two directional casters with the same structural height

More casters are arranged, suitable for traction operation. The transport equipment can be well guided when going straight and turning, and it is easy to turn at a fixed point. It is especially suitable for heavy loads and long instruments. In order to achieve controllability, the directional casters must always be in contact with the ground.

If you don’t use the directional caster in the middle, you can also use two single wheels on one shaft. This arrangement has strong bearing capacity, good mobility, good guiding performance when traveling straight, and better overturning stability.

Product detail pictures:

Related Product Guide:

Our business puts emphasis on the administration, the introduction of talented personnel, as well as the construction of team building, trying hard to further improve the standard and liability consciousness of staff members customers. Our enterprise successfully attained IS9001 Certification and European CE Certification of Reasonable price for Tpr Wheel - EF6 Series Top plate type-Swivel/Rigid(Round)(Zinc-plating) – GLOBE , The product will supply to all over the world, such as: Ireland, Gabon, Brunei, We look forward to hearing from you, whether you are a returning customer or a new one. We hope you will find what you are looking for here, if not, please contact us immediately. We pride ourselves on top notch customer service and response. Thank you for your business and support!

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.