Quality Inspection for Floor Lock Brakes - Caster OEM China Manufacturer Industry Trolley High Quality PU Wheels – GLOBE

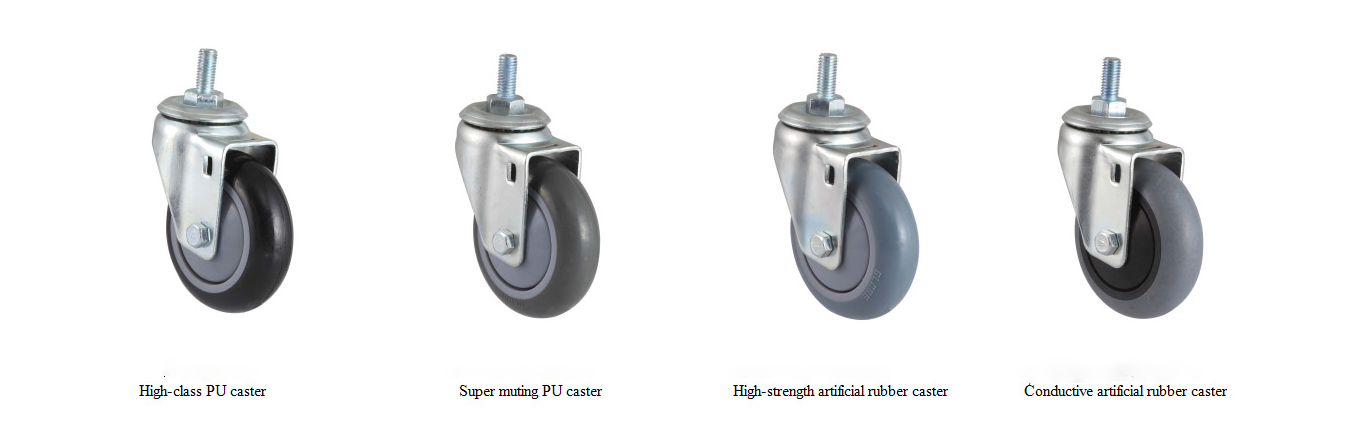

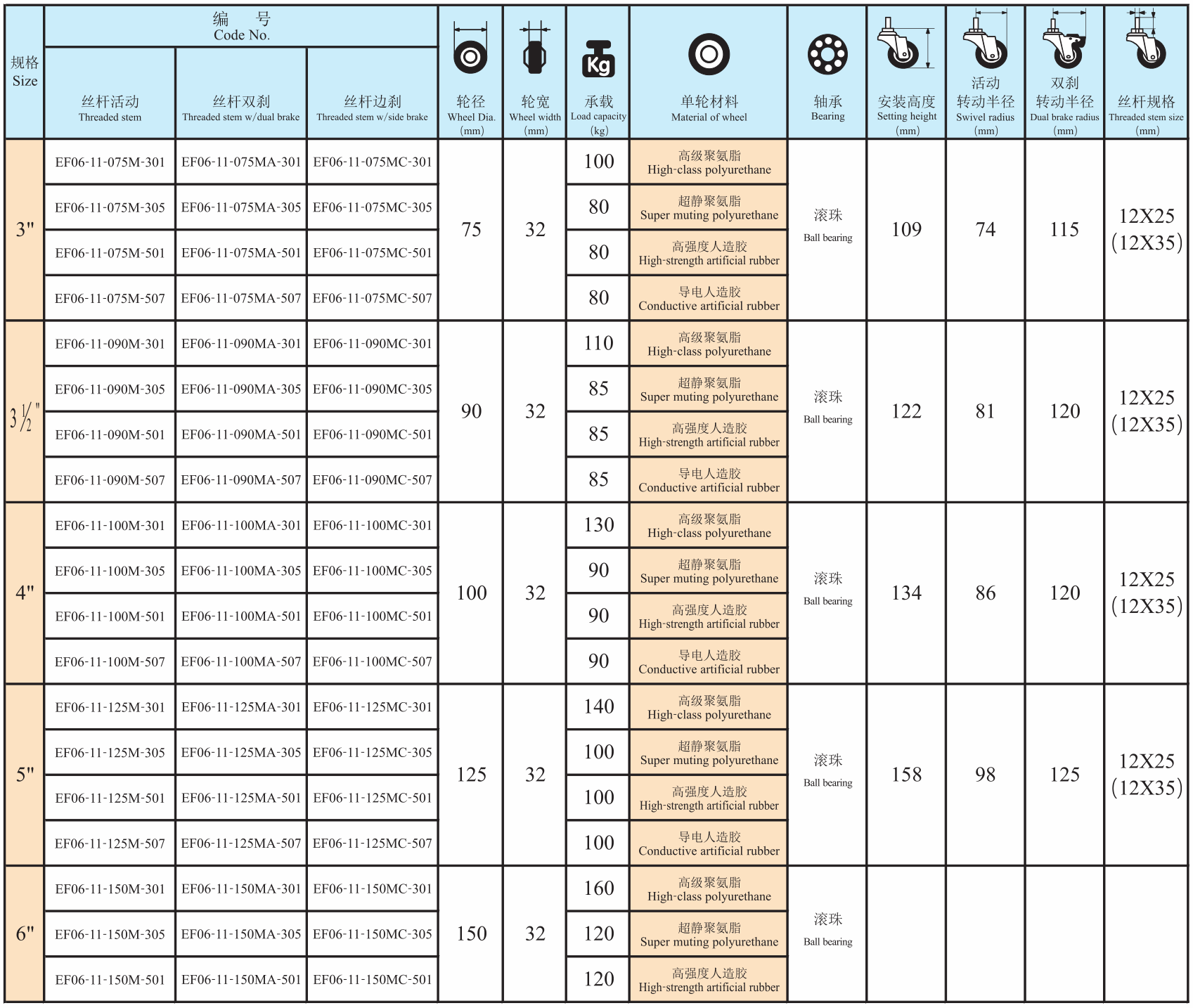

Quality Inspection for Floor Lock Brakes - Caster OEM China Manufacturer Industry Trolley High Quality PU Wheels – GLOBE Detail:

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

Surface treatment methods and characteristics of industrial casters

Friends who have used casters know that all kinds of industrial caster brackets have been surface-treated; whether yours is a fixed caster bracket or a swivel caster bracket, why do the caster manufacturers need to surface the bracket? This is mainly because the brackets are stamped with iron or steel, and in our daily use, because iron or steel is easily oxidized with oxygen, the entire bracket will rust, affecting the surface and normal use. This is why so many Caster manufacturers must subject the caster bracket to surface treatment.

The caster bracket has a lot of surface treatment. We usually see galvanization. Because of its strong applicability and low cost, everyone is also fond of it; what are the surface treatment methods for the caster bracket? And what are the differences in the surface treatment characteristics of these caster brackets?

Galvanized: Features: The new oxide is denser and protects the inner metal from oxidation and corrosion.

Plastic spray: Features: Compared with traditional spray paint, it is more resistant to friction and impact. The appearance of the coating is excellent in quality, and the adhesion and mechanical strength are strong.

Color galvanized: Features: protect the internal metal from corrosion, and the appearance of the product is more beautiful.

Electrophoretic: Features: strong adhesion, the paint film is not easy to fall off, continuous bending does not break the skin, and the thickness of the paint film in any part of the workpiece is uniform. Eliminates the undesirable faults such as crusts and tear marks during spraying. Comply with environmental protection, water-based paint, non-toxic, non-polluting, and no residues of harmful substances.

Regardless of whether the caster bracket is Galvanized, Plastic spray, Color galvanized or Electrophoretic, these surface treatments are to prevent the caster bracket from being corroded. And their surface treatment methods are different, and their characteristics are different, so the final effect is also different. Therefore, when we choose which type of caster surface treatment method, we should choose different surface treatment methods according to the needs.

Product detail pictures:

Related Product Guide:

Dependable high-quality and fantastic credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality very first, client supreme" for Quality Inspection for Floor Lock Brakes - Caster OEM China Manufacturer Industry Trolley High Quality PU Wheels – GLOBE , The product will supply to all over the world, such as: Accra, Bhutan, Peru, we always keep our credit and mutual benefit to our client, insist our high quality service to moving our clients. always welcome the our friends and clients to come and visit our company and guid our business, if you are interested in our products, you can also submit your purchase information online, and we will contact you immediately, we keep our highly sincere cooperation and wish everything in your side are all well.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly