Popular Design for V Cast Iron Grooved Wheels - Dustbin Rubber Caster Factories Industrial Wheels Stem Type With Brake – GLOBE

Popular Design for V Cast Iron Grooved Wheels - Dustbin Rubber Caster Factories Industrial Wheels Stem Type With Brake – GLOBE Detail:

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

What is the material of anti-static casters?

Anti-static casters can absorb the static electricity generated around them, so why does it have such a magical function? In fact, it is determined by the materials used in the production of anti-static casters. Below, the editor of Global Caster Factory will introduce the materials used for anti-static casters:

1. Rubber material

The resistance is large, almost insulated, and it can absorb the surrounding static electricity. The rubber material can be divided into many types, and everyone can choose according to the actual situation.

2. Anti-static polyurethane material

Polyurethane is an artificial synthetic material with very strong plasticity. It can be adjusted to produce anti-static polyurethane material

3. Other materials with higher resistance

As long as it is a material with a higher resistance, it can be considered, but in addition to the higher resistance, it must also meet the requirements for the use of normal casters.

In short, anti-static casters are used to absorb the static electricity generated by friction and the surrounding of the casters, and to protect the precision electronic components from being damaged by the static ring. They are commonly found in anti-static workshops. The key point for anti-static casters is that they can prevent static electricity. The production material of the anti-static wheel!

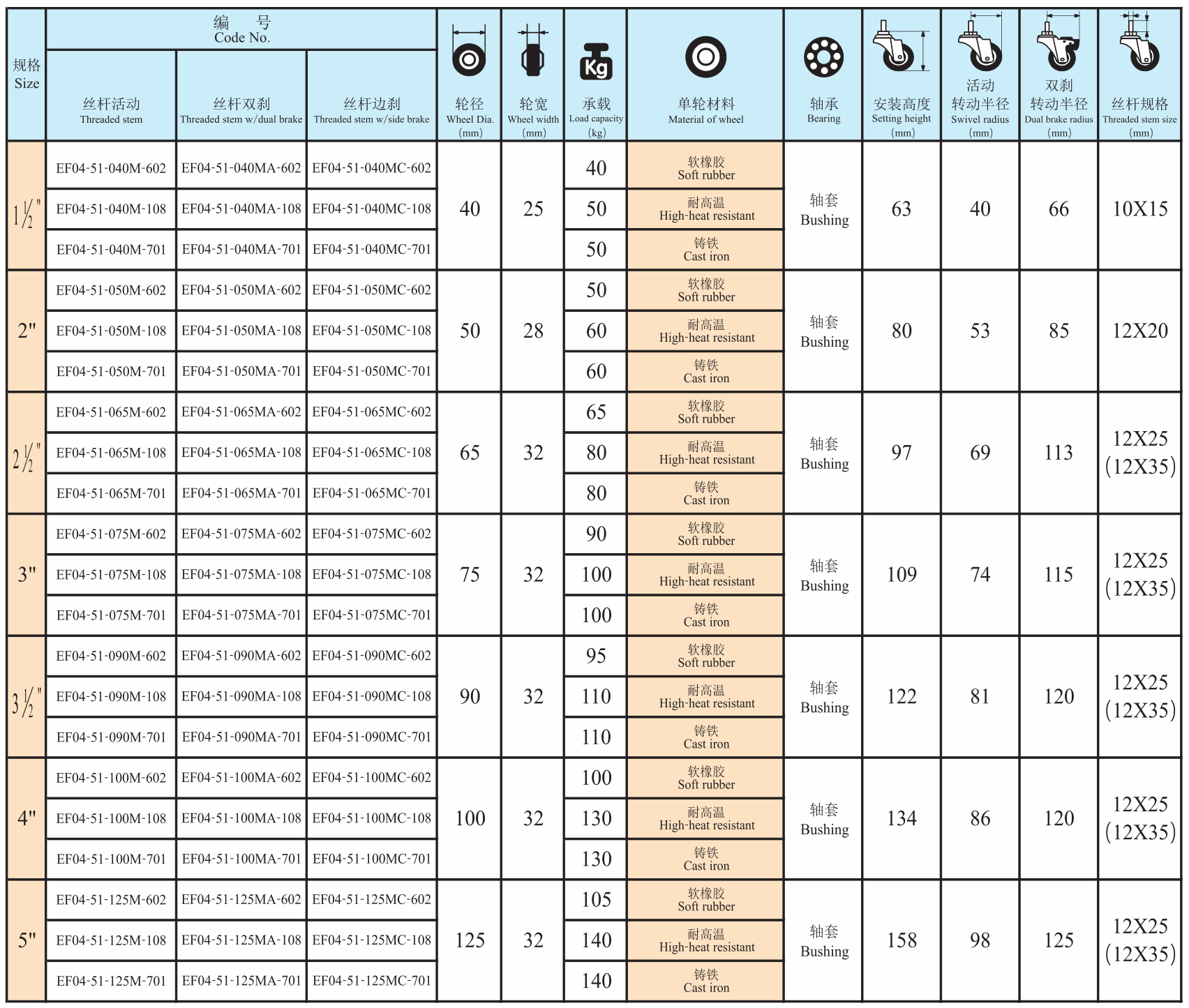

Product detail pictures:

Related Product Guide:

The incredibly abundant projects administration experiences and 1 to one provider model make the superior importance of small business communication and our easy understanding of your expectations for Popular Design for V Cast Iron Grooved Wheels - Dustbin Rubber Caster Factories Industrial Wheels Stem Type With Brake – GLOBE , The product will supply to all over the world, such as: Iran, New Delhi, Israel, Furthermore, all of our items are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our goods, please don't hesitate to contact us. We will do our best to meet your needs.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.