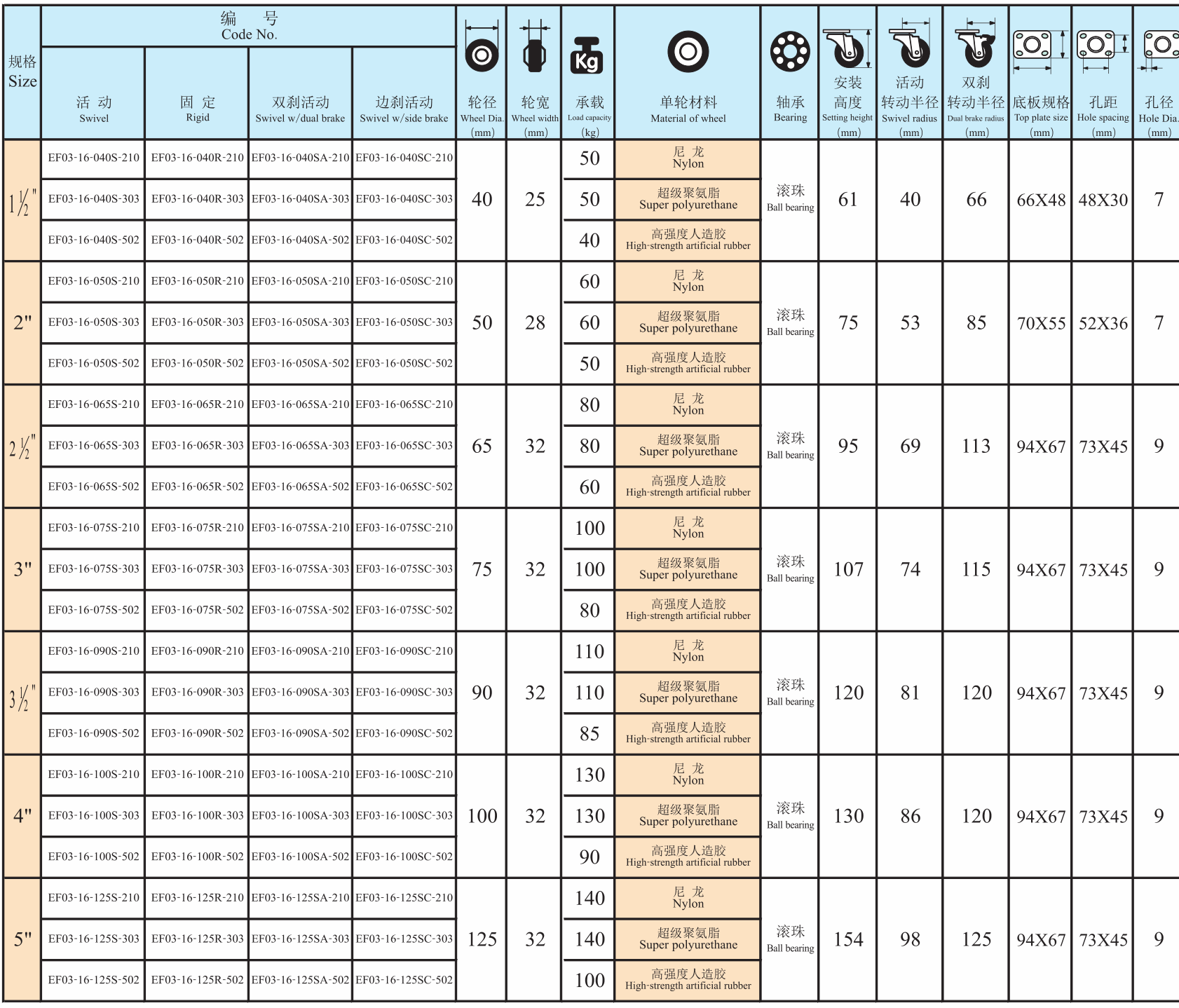

Ordinary Discount China Castor Company - EF3 Series-Top plate type-Swivel/Rigid(Stainless steel) – GLOBE

Ordinary Discount China Castor Company - EF3 Series-Top plate type-Swivel/Rigid(Stainless steel) – GLOBE Detail:

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

How to distinguish the quality of medium duty casters

1. Judging by the appearance of the medium wheels support frame, the medium size heavy plate support frame has a beautiful surface, no burrs and symmetrical thickness, so the quality of the load is guaranteed;

2. Support frame in hot galvanized steel for medium weight rollers. Hot dip galvanizing technology is commonly used to prevent corrosion. Ask how smooth and shiny the hot dip galvanized support frame for medium weight rolls should be;

3. Electric welding of medium weight pulley support frame and electrofusion welding of thick steel sheet must be smooth and no welding, leaking, etc. is required.

4. standards for conventional and medium wheels;

5. Check the surface layer of the wet rollers of medium density, without streaks, correct color and without significant shades;

6. Know the general effect of generic intermediate roles. As the solid plate rotates, any rigid sphere must be able to touch the varying surface of the thick steel plate. The lifting capacity must be proportional and the rotation must be skilful, without obvious interruptions;

7. Learn to use medium wheels. Bringing quality. Medium weight wheels should not experience strong vibrations when cornering.

Product detail pictures:

Related Product Guide:

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for Ordinary Discount China Castor Company - EF3 Series-Top plate type-Swivel/Rigid(Stainless steel) – GLOBE , The product will supply to all over the world, such as: Georgia, kazan, Germany, If you give us a list of products you are interested in, along with makes and models, we can send you quotations. Please email us directly. Our goal is to establish long-term and mutually profitable business relationships with domestic and overseas clients. We look forward to receiving your reply soon.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!