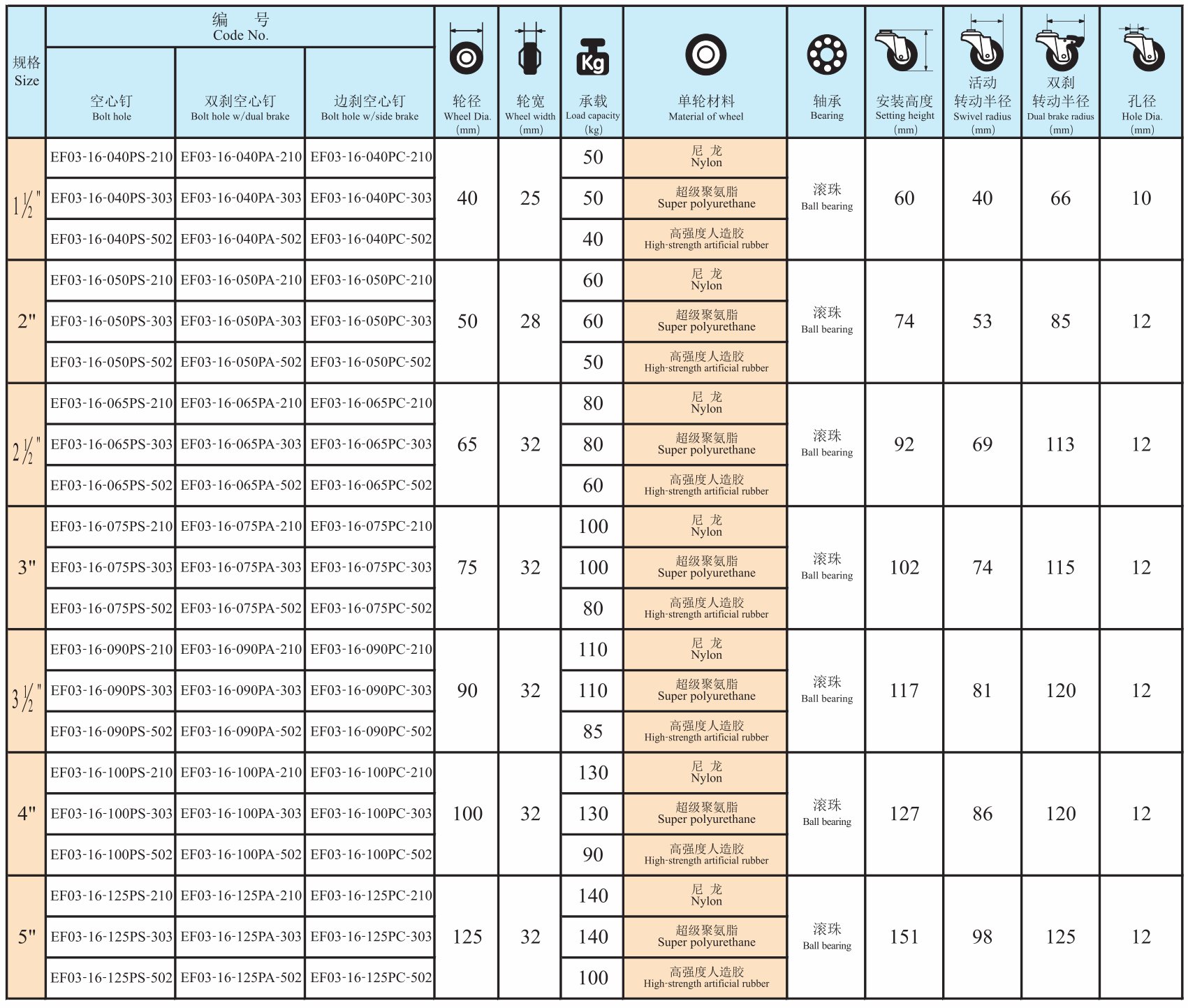

Online Exporter Threaded Stem Caster With Brake - EF3 Series-Bolt hole type(Stainless steel) – GLOBE

Online Exporter Threaded Stem Caster With Brake - EF3 Series-Bolt hole type(Stainless steel) – GLOBE Detail:

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

How to choose medium rolls?

1. Select medium-sized castors, both soft and hard materials.

Wheels usually include nylon wheels, super polyurethane wheels, heavy duty polyurethane wheels, heavy duty synthetic rubber wheels, iron wheels and air pump wheels. Super polyurethane wheels and heavy-duty polyurethane wheels meet your driving needs, whether you are driving on the ground indoors or outdoors; High strength synthetic rubber wheels can be used for hotel, medical equipment, flooring, wooden flooring, tiled flooring, etc. Walking requires a calm and silent surface; Nylon wheels and iron wheels are suitable for places with an uneven floor or iron filings on the ground; and air pumps are suitable for light loads and smooth, uneven roads.

2. Select medium-sized rolls for greater flexibility in rotation.

The bigger the wheel, the more labor-saving, the roller bearing can bear heavy loads, and the strength is greater when rotating – the wheel is equipped with high-quality ball bearings (made of rolled steel) that can withstand heavier loads and rotate. easier and more flexible peacefully.

3. Select medium temperature rolls.

Extreme cold and high temperatures have a huge impact on medium-sized wheels. The polyurethane wheels can rotate flexibly in cold temperatures down to minus 45 ° C and the high temperature resistant wheels can rotate easily in high temperatures up to 275 ° C.

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Online Exporter Threaded Stem Caster With Brake - EF3 Series-Bolt hole type(Stainless steel) – GLOBE , The product will supply to all over the world, such as: South Korea, Estonia, Paraguay, We are increasingly expanding our international market share based on quality products, excellent service, reasonable price and timely delivery. Please contact us at any time for more information.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.