How to choose Globe Casters

Using casters can reduce the work force and increase the work efficiency.The right caster should be chosen by the manner of application.condition and request(for example facility, labour saving.durability).Tho factors must be considered as follows:

■ The load capacity

(1) Load:T=(E+Z)/M

T=each caster load

E=the weight of the vehicle

Z=the welght of moving object

M=efficient load casters quantity(the position and different heavy distribution must be considered)

■ Agility

(1) The accessories with small friction(e.g.the ball bearing) or those after special treatment(e.g. quenching) should be chosen to assemble the turning part of a caster (the turn of the frame and the roll of the wheel),in order to make the caster flexible,durable and moving easily.

(2) Greater eccentricity, more flexible turning.The load capacity is relevant to be reduced.

(3) The bigger diameter of the wheel is, the less force is required to push, and it is also more friendly to the floor.For a same distance, a bigger wheel rolls more slowly comparing with a smaller one. Slow rlling reduces the heat generation and distortion.It makes bigger wheels more durable.Choose a bigger wheel if mounting height is allowed.

■ Moving speed

The request of caster speed:at the mormal temperature and on the smooth floor,the speed should be lower than 4KMH and there are static intervals during the working time.

■ Applied environment

The floor materials ,barriers,leftovers and the special environment,such as iron scraps,high or low temperature,great acidity and alkalescence,oil liquor,chemistry solvent and anti-static-electricity,should be considered when choosing the caster.The caster used in special environment should be made of special materials.

■ Mounting notice:

Plate:the ftted plate must be leveled, hard and firm.Plate:the ftted plate must be leveled, hard and firm.Threaded: A spring shim should be fitted together to avoid loosing.

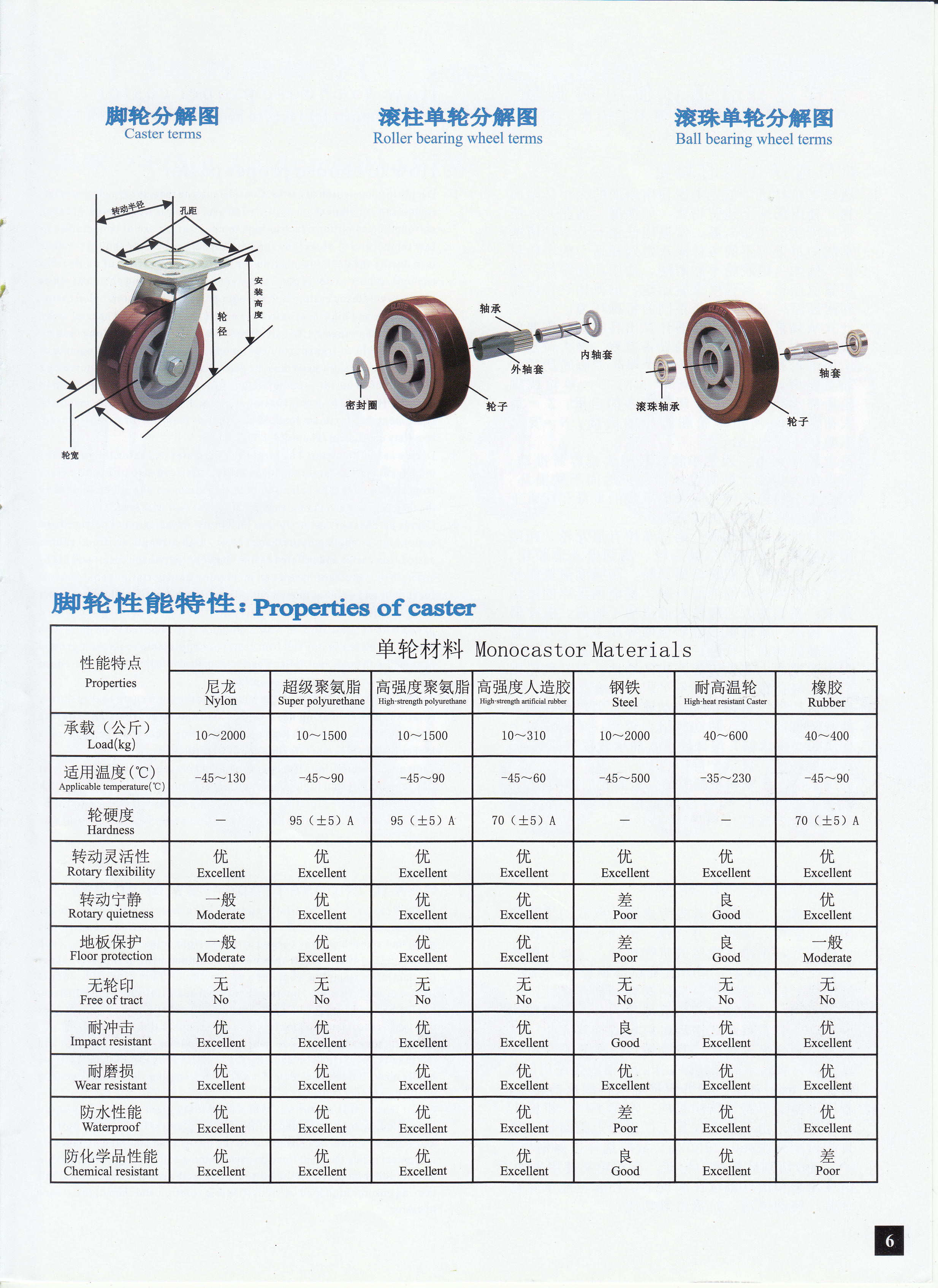

■ Wheel Material Capability & Characteristic

Post time: Nov-03-2022