Developing a reasonable inventory plan can help you achieve good inventory management, avoid excessive or insufficient inventory, and improve operational efficiency and capital utilization. Here are some steps and suggestions to help you develop a sound inventory plan:

1. Analyze sales data: Review sales data over a period of time to identify product sales trends and seasonal demand changes. Understand your top-selling products, your slow-selling products, and how your sales fluctuate.

2. Determine Inventory Levels: Based on sales data and demand forecasts, determine the inventory levels you want to keep in inventory. This can be determined based on sales forecasts, lead times, and the characteristics of customer demand.

3. Set safety stock: Set appropriate safety stock levels based on supplier reliability and uncertainty in supply cycles. Ensure adequate inventory is available to respond to unexpected demand, supply chain delays, or other unforeseen circumstances.

4. Optimize purchasing plans: Develop purchasing plans based on sales forecasts and inventory targets. Ensure timely procurement of required raw materials or products and avoid over-purchasing leading to inventory backlog.

5. Seek supplier collaboration: Build long-term relationships with reliable suppliers and share sales forecasts and inventory goals. This allows for better coordination of the supply chain and reduces supply chain delays and inventory risks. Regular inventory counts: Conduct regular inventory counts to ensure the accuracy of inventory data. Inventory discrepancies, product losses, or expiration issues can be identified and resolved through inventory counting. Use inventory management tools: Track inventory levels, sales data and purchase orders with modern inventory management tools and software. These tools provide real-time inventory status and alerts to help you make more accurate inventory decisions. Continuous optimization: Regularly review and evaluate the effectiveness of the inventory plan, and make adjustments and improvements based on actual conditions. As markets and supply chains change, your inventory plan needs to continually optimize and adapt to new conditions. To sum up, a reasonable inventory plan needs to be developed based on sales data, demand forecasts and supply chain conditions. With effective inventory management, you can reduce inventory costs, increase return on capital, and ensure smooth supply chain operations.

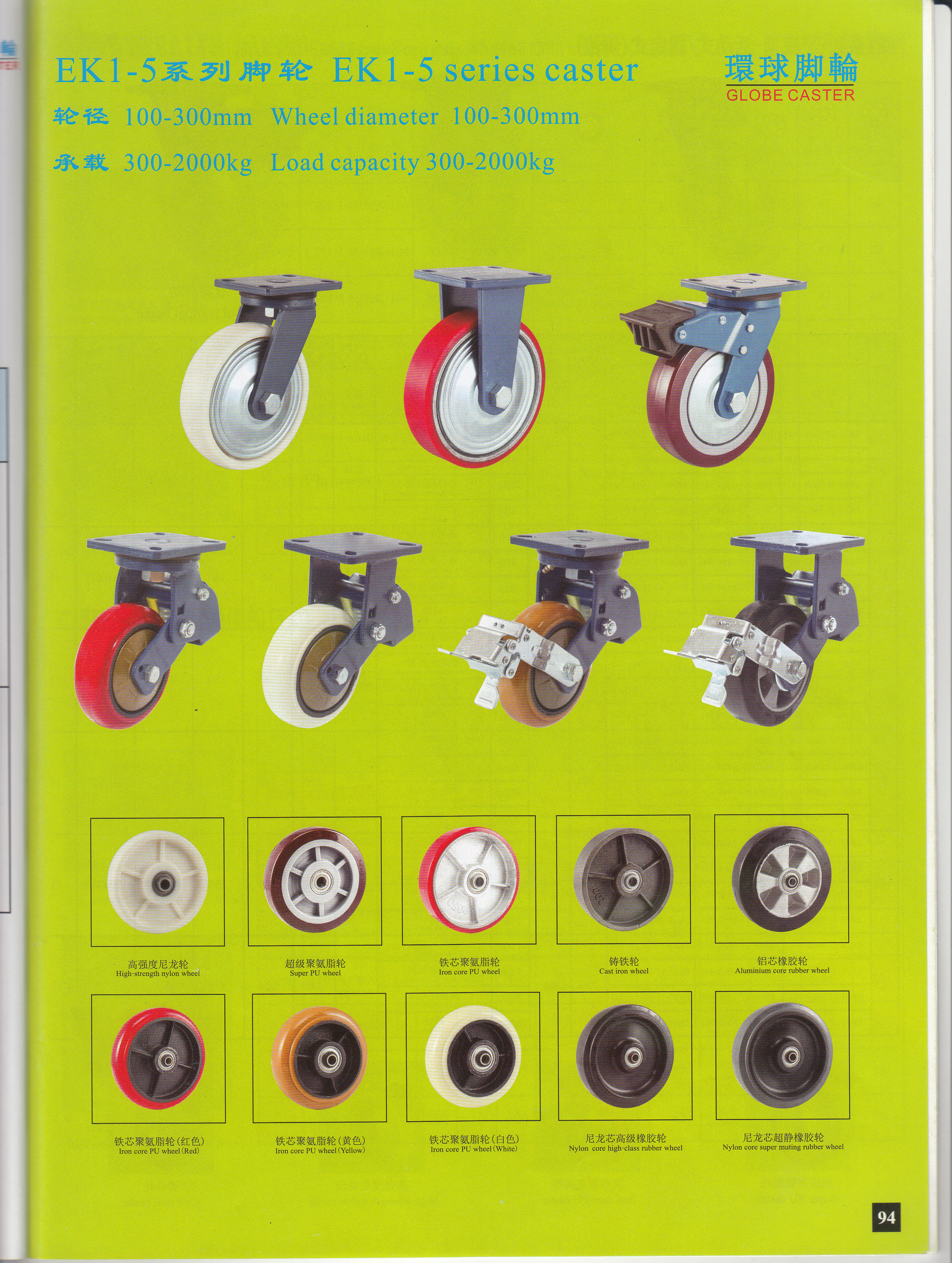

The end of 2024 is approaching, please prepare your inventory plan. As usual, Foshan Globe Cater factory will become busier as the end of the year approaches

Post time: Nov-15-2023