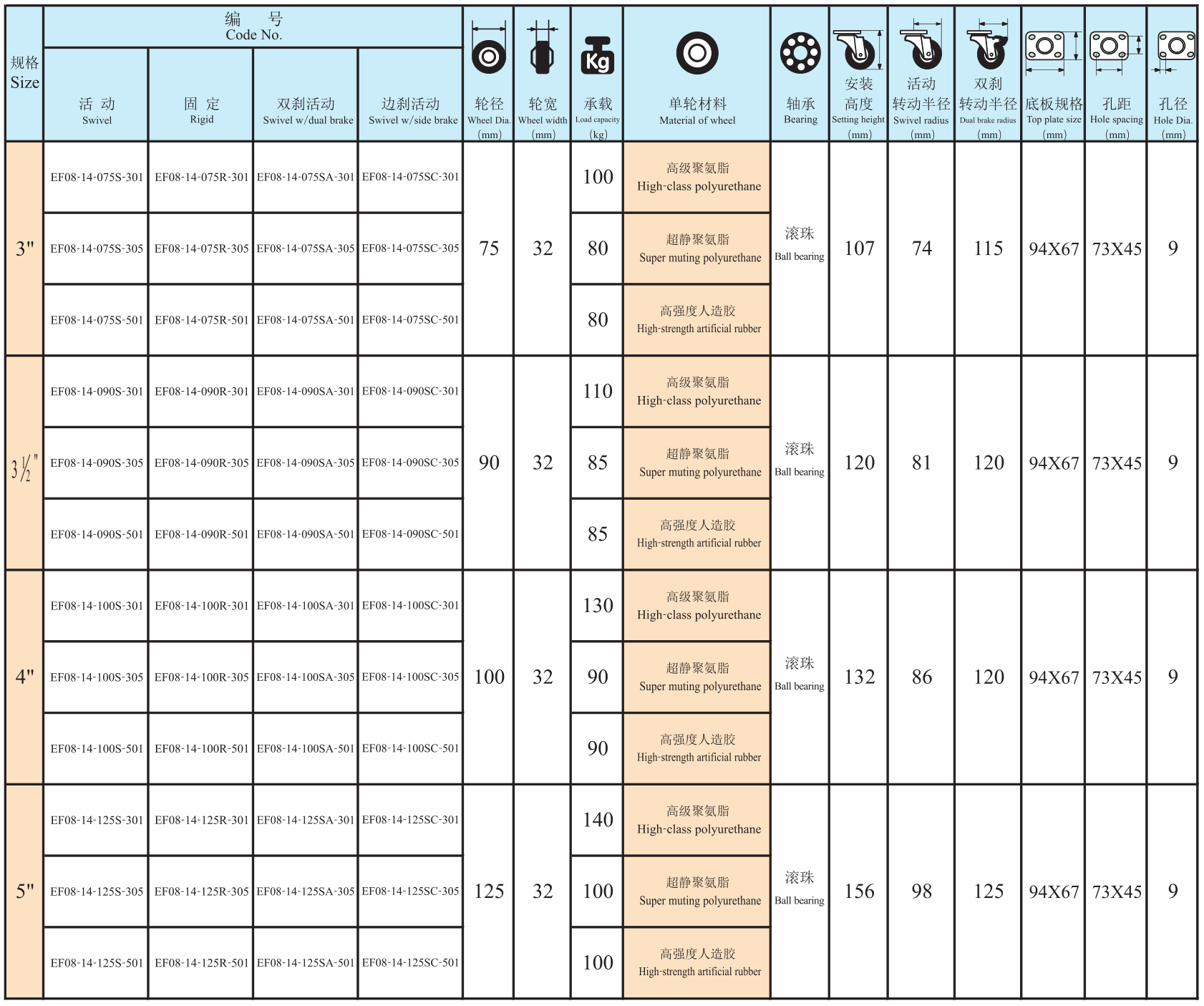

Hot Selling for Caster In Spanish - EF8 Series-Top plate- Swivel/Rigid (Round)(Chrome-plating) – GLOBE

Hot Selling for Caster In Spanish - EF8 Series-Top plate- Swivel/Rigid (Round)(Chrome-plating) – GLOBE Detail:

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

What is the difference between different universal caster wheels?

Because there are different types of swivel casters, they can be used in different fields. The wheels in this area can rotate, but they cannot rotate. So, what is the difference and difference between casters that can be turned and those that cannot be turned?

For these two types of universal casters, because of their different functions, they also have different main uses. The revolving wheel can be used for food delivery in restaurants, not the revolving wheel can be used for food delivery with a high degree of mechanical automation. Because the raw materials used in the production of these non-rotating universal wheels are relatively hard, many processing plants use such universal casters, which are much better than that one wheel.

There are differences between different universal casters, but regardless of the difference, everyone needs to pay attention to the following key content when producing casters

1. Check the visible damage level of the tire surface. The “grind spots” on the tire surface can indicate that there is dirt deposits. Dirt such as stainless steel wire is likely to be coiled around the wheel. Remove the anchor bolts and nuts on the wheel to remove the dirt. Check whether the rolling bearing of the wheel is damaged. If the parts are not damaged, they can be assembled again and used again. If you often encounter a situation where the wheel is entangled with dirt, it is recommended to install an anti-winding cover to prevent it.

2. The casters of universal wheels are loose or jammed, which can also cause “grind spots”. Appropriate maintenance and inspection are required. The manufacturer of universal wheels especially needs to check the tightness of the anchor bolts and the amount of grease used. Destroyed casters can improve the turning characteristics and rotation coordination capabilities of machinery and equipment.

3. Resistor characteristic experiment:

When testing this feature, the casters should be kept dry and clean. Place the caster on the metal sheet that is insulated from the road surface, keep the edge of the wheel in contact with the metal sheet, and add 5% to 10% of the rated load on the caster. Use an insulating layer insulation tester to accurately measure the resistance between the caster and the metal sheet (tolerance open circuit voltage 500V, accurate measurement of resistance fluctuations within 10%, product loss no more than 3W). For electric conductor type casters, the resistance value should not exceed 104 ohm mothers, and the resistor of the caster should be between 105 and 107 ohm mothers.

4. Impact test:

All objects are likely to cause shock and vibration due to transportation, application, storage and other standards, so that the product cannot be used normally for a period of time. Furniture is usually very vulnerable to damage due to its own specifications, net weight and other characteristics, and is located on the bottom. The casters at the end should distinguish whether the furniture is stable or not, and should have excellent impact resistance.

In short, the difference between different universal casters is quite different, because the universal caster only represents a parameter of the caster, and the caster will have different characteristics according to different functions and parameters, and according to these differences The characteristics of these different universal casters will be used in different scenarios.

Product detail pictures:

Related Product Guide:

As for aggressive costs, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such high-quality at such rates we have been the lowest around for Hot Selling for Caster In Spanish - EF8 Series-Top plate- Swivel/Rigid (Round)(Chrome-plating) – GLOBE , The product will supply to all over the world, such as: Rwanda, Denver, California, Our tenet is "integrity first, quality best". We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!