Hot sale High Quality Industrial Caster - EB2 Series-Top plate type-Swivel/Rigid(Zinc plating) – GLOBE

Hot sale High Quality Industrial Caster - EB2 Series-Top plate type-Swivel/Rigid(Zinc plating) – GLOBE Detail:

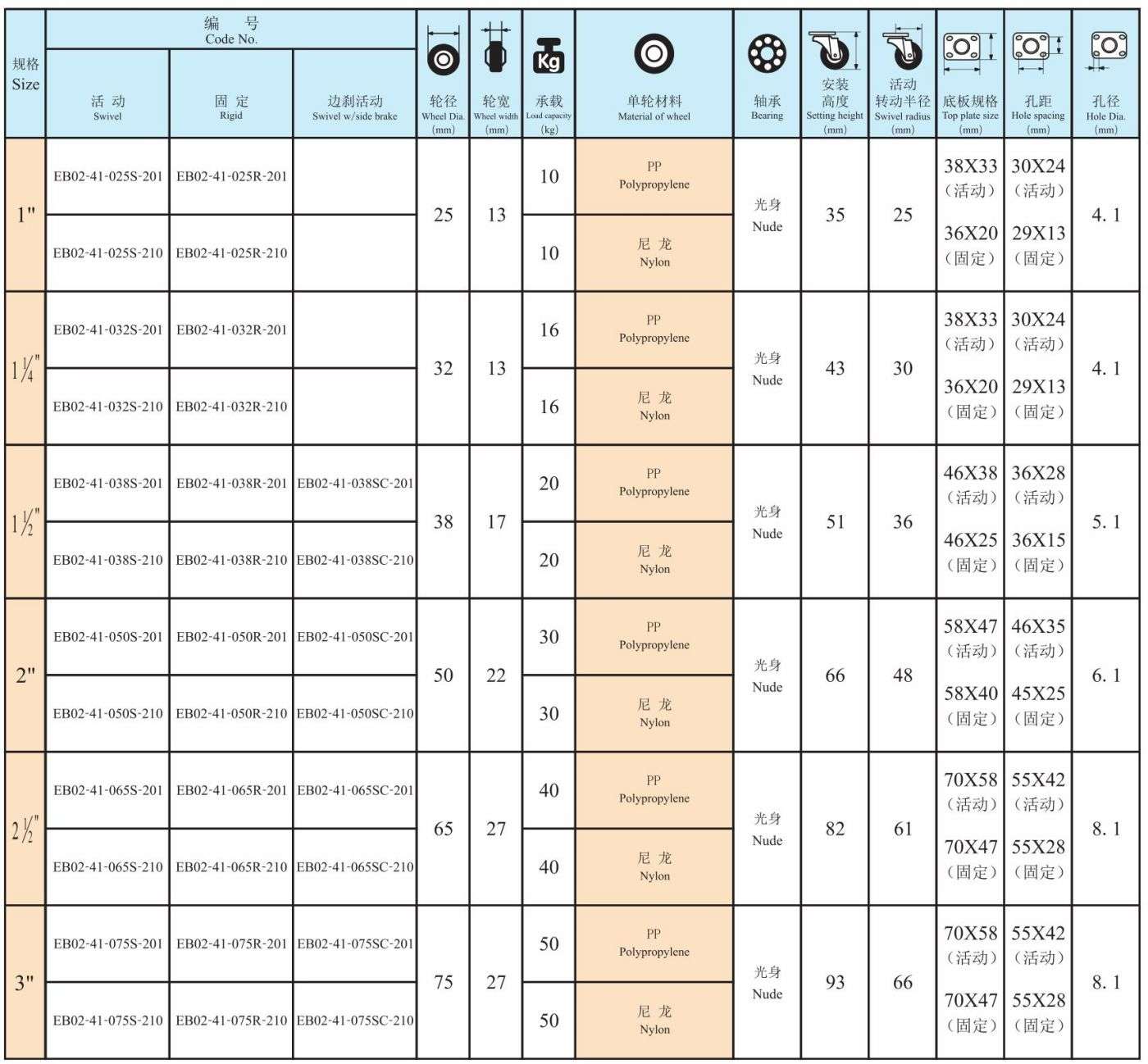

PP caster

Nylon caster

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

The application of casters drives the rhythm of the world

The simplest invention has changed the way humans carry and move goods. It can be said that the emergence of casters is a revolution and progress. Among them, industrial casters are mainly used in trolleys, mobile scaffolding, workshop trucks, etc.

There are many types of industrial casters, which are different in size, model, and tire surface. Choosing the right wheel is based on the following conditions: use the site environment. The weight of the product. The working environment contains chemicals, grease, oil, salt and other substances. Various special climates, such as humidity, high temperature or severe cold, are required for impact resistance, collision and driving quietness.

The structure of industrial casters consists of a single wheel mounted on a bracket, which is used to install under the equipment so that it can move freely. Casters are mainly divided into two categories: fixed casters. The fixed bracket is equipped with a single wheel and can only move in a straight line. Movable casters The 360-degree steering bracket is equipped with a single wheel, which can drive in any direction at will.

Choose anastomosis caster wheels: general wheels are made of nylon, rubber, polyurethane, elastic rubber core covered with polyurethane, cast iron, plastic, etc. Plastic wheels are often used in high-humidity environments. Iron-core polyurethane wheels are generally used in high-load factories and logistics vehicles. Different casters are selected according to different usage scenarios.

Choosing caster bracket: Generally, load-bearing casters should be considered first, such as supermarkets, homes, schools, hospitals, office buildings, hotels and other places. Because the air is good and smooth, each caster can carry 50-150 kilograms, and the load is small. Generally 3- The 4mm steel plate is stamped, welded and formed, and the caster wheel bracket is electroplated.

Total load on casters: the maximum load and the number of casters.

Swivel caster diameter: Generally, the larger the diameter of the wheel, the smaller the pushing load. It means that a larger one can better take care of the ground not being damaged. The diameter of the wheel of the selected size should be considered at the beginning of the choice of carrying the weight of the van under the initial thrust load.

The single wheel with greater maneuverability to ensure the rotation of the wheel is more labor-saving. The needle-shaped roller bearing can carry heavier loads and move more resistance; single-wheel-mounted quality ball bearings can carry heavier loads and roll more effectively.

Product detail pictures:

Related Product Guide:

It is a great way to further improve our products and repair. Our mission is always to create innovative products to prospects with a superior expertise for Hot sale High Quality Industrial Caster - EB2 Series-Top plate type-Swivel/Rigid(Zinc plating) – GLOBE , The product will supply to all over the world, such as: Moscow, Angola, Honduras, Our company covers an area of 20, 000 square meters. We have more than 200 workers, professional technical team, 15 years' experience, exquisite workmanship, stable and reliable quality, competitive price and sufficient production capacity, this is how we make our customers stronger. If you have any inquiry, please do not hesitate to contact us.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.