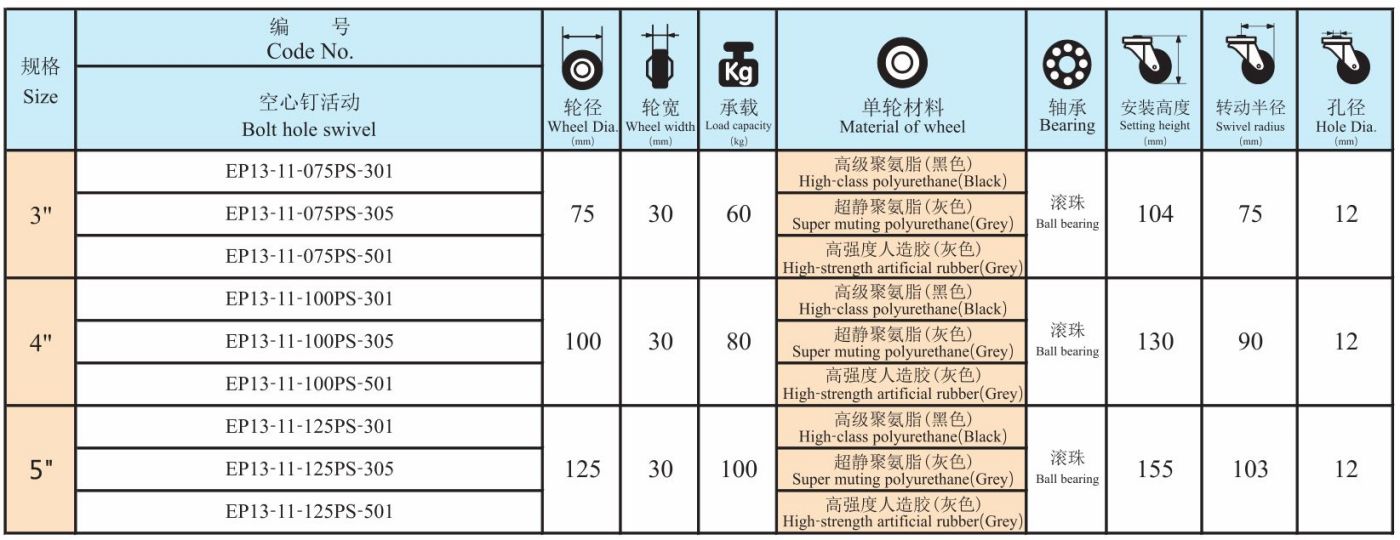

Good Quality Trolley Caster - EP 13 Series Bolt hole swivel type(heat treatment fork) – GLOBE

Good Quality Trolley Caster - EP 13 Series Bolt hole swivel type(heat treatment fork) – GLOBE Detail:

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

Five factors to consider when choosing industrial casters

Many users said that although the quality of the industrial casters they purchased was very good, they could not fully meet their actual needs. When choosing, the different materials, styles and load-bearing capacity of industrial casters make customers find it difficult to choose and cannot take all aspects into consideration. In fact, it is not difficult to choose industrial casters. You only need to consider five factors according to your own situation to choose a caster suitable for your use.

Today, Globe Caster will introduce these five factors to everyone:

(1) Carrying capacity. Decide the weight of the load, the size of the wheel, and also affect the rotatability of industrial casters. Ball bearings are suitable for heavier load requirements of more than 180 kg.

(2) Conditions of use of the venue. Choose a wheel large enough to accommodate the cracks in the scene. Also consider the size of the road surface, obstacles and other factors.

(3) Special environment. Each wheel adapts to a different working environment, and choose the appropriate one to adapt to the special environment. For example, traditional rubber is not resistant to acids, oils and chemicals, so it is necessary to choose the corresponding industrial casters according to the use environment.

(4) Rotation flexibility. The larger the wheel, the less effort it can turn. Industrial caster ball bearings can carry heavier loads, and ball bearings rotate more flexibly but carry lighter loads.

(5) Temperature limit. Severe cold and heat may cause troubles to many wheels. High-quality green grease should be selected to ensure that industrial casters can be used for high temperatures from -40°C to 165°C.

After reading the introduction of Globe Caster, do you think the idea of purchasing industrial casters has become clearer? Although the quality of industrial casters is very important, it is the key to the problem that they are suitable for their own use. As long as you take these five factors into account and combine your own actual conditions, you will no longer have to make the purchase of industrial casters.

Product detail pictures:

Related Product Guide:

We keep on with our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We intention to create extra worth for our buyers with our prosperous resources, superior machinery, experienced workers and superb services for Good Quality Trolley Caster - EP 13 Series Bolt hole swivel type(heat treatment fork) – GLOBE , The product will supply to all over the world, such as: Cologne, Maldives, Pretoria, We strongly believe that technology and service is our base today and quality will create our reliable walls of future. Only we've got better and better quality , could we achieve our customers and ourselves, too. Welcome customers all over the word to contact us for getting further business and reliable relationships. We have been always here working for your demands whenever you require.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.