Factory wholesale Caster Light Duty - Stainless Steel Heay Duty Industrial Top plate-Swivel/Rigid/ Dual Brake Endurant Caster – GLOBE

Factory wholesale Caster Light Duty - Stainless Steel Heay Duty Industrial Top plate-Swivel/Rigid/ Dual Brake Endurant Caster – GLOBE Detail:

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

Heavy duty wheels and casters

Heavy-duty wheels and casters are suitable for heavy loads and higher walking speeds.

Their structure is particularly stable. In order to partly withstand high loads, casters with two wheels (double casters) are also used in this area. Casters with damping springs are especially suitable for vibration-free transportation.

Typical uses include shelf trucks and industrial trucks, assembly systems and transportation systems.

According to DIN EN 12532, the bearing capacity test is carried out at a speed of 4 km/h, or at a higher speed in accordance with DIN EN 12533, the test is carried out on a rotating plate:

The most important inspection conditions are in accordance with DIN EN 12532:

• Speed: 4 km/h

• Temperature: Temperature: +15°C to +28°C

• Hard horizontal wheels and obstacles, the height of the obstacles is as follows:

Wheel with soft tread, 5% of wheel diameter (hardness <90°Shore A)

Wheel with hard tread, 2.5% of wheel diameter (hardness ≥90°Shore A)

• The test time is 15000*single wheel circumference when crossing obstacles at least 500 times

• Pause time: 1 minute maximum after every 3 minutes of walking time

The most important inspection conditions refer to the regulations of DIN EN 12533:

• Speed: 6 km/h, 10 km/h, 16 km/h, 25 km/h (standard: maximum 16 km/h)

• Temperature: Temperature: +15°C to +28°C

• Hard horizontal wheels and obstacles, the height of the obstacles is as follows:

Wheel with soft tread, 5% of wheel diameter (hardness <90°Shore A)

Wheel with hard tread, 2.5% of wheel diameter (hardness ≥90°Shore A)

• Test time: The required number of crossing obstacles is equivalent to five times the wheel diameter (mm).

• Pause time: 1 minute maximum after every 3 minutes of walking time

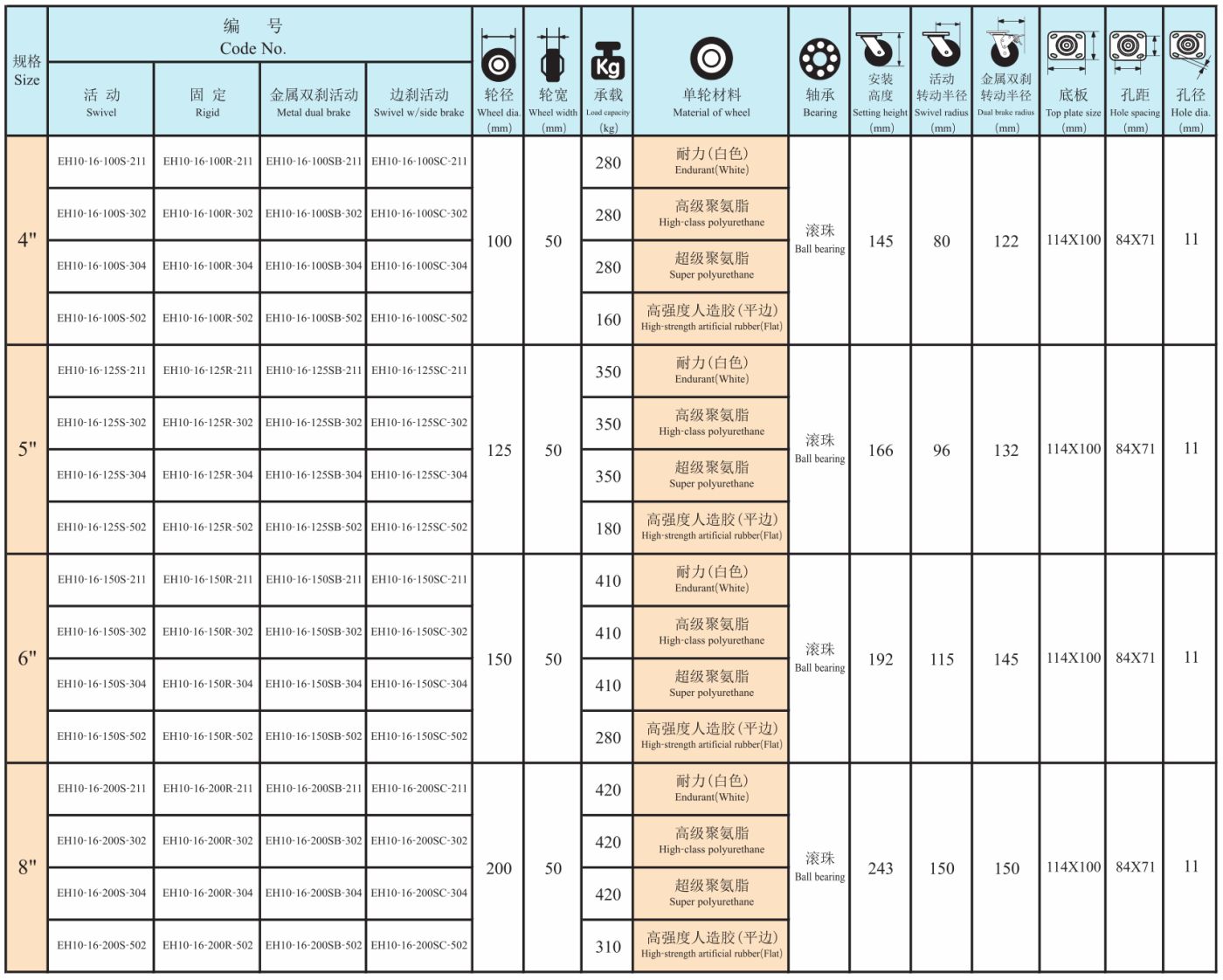

Product detail pictures:

Related Product Guide:

We insist about the theory of growth of 'High excellent, Performance, Sincerity and Down-to-earth working approach' to offer you with great company of processing for Factory wholesale Caster Light Duty - Stainless Steel Heay Duty Industrial Top plate-Swivel/Rigid/ Dual Brake Endurant Caster – GLOBE , The product will supply to all over the world, such as: Karachi, Pakistan, Serbia, It is our customers' satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We offer wholesale prices on all our quality parts so you are guaranteed greater savings.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!