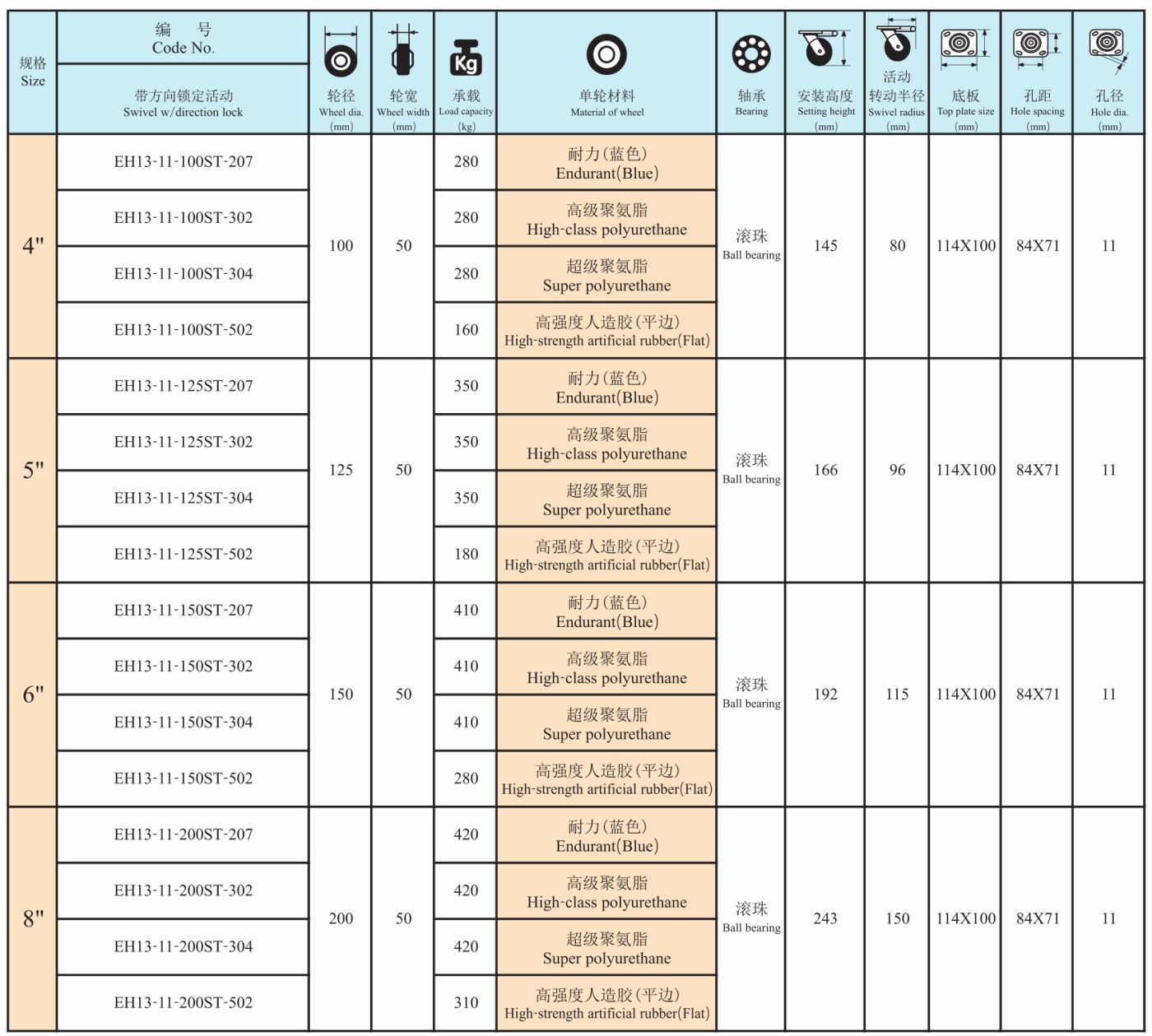

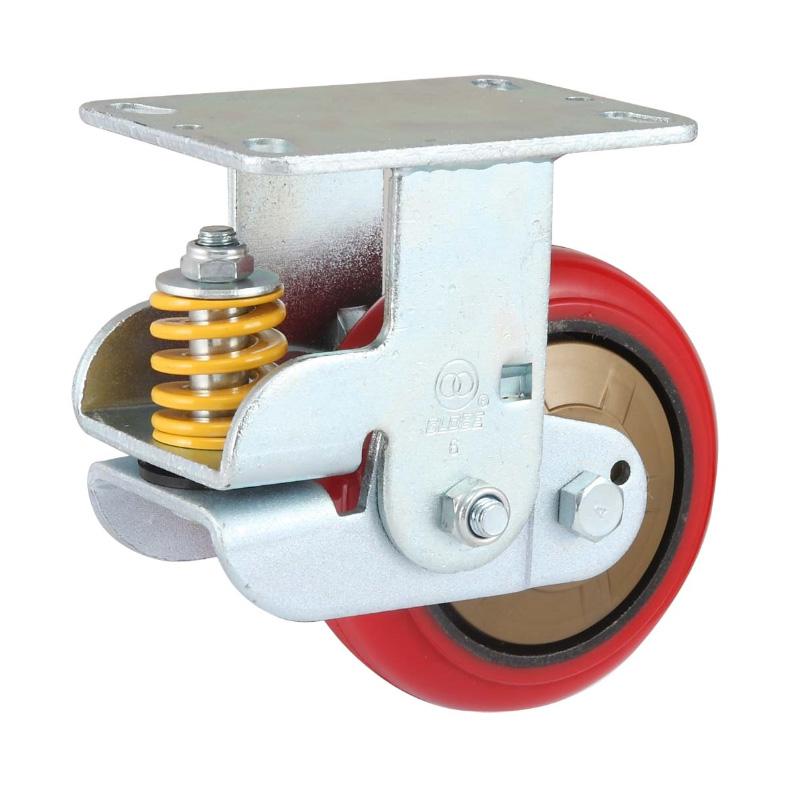

Factory Outlets Metal Caster - Heavy Duty Direction lock Swivel TPR/Endurant/PU Caster Wheel(Zinc-plating) – GLOBE

Factory Outlets Metal Caster - Heavy Duty Direction lock Swivel TPR/Endurant/PU Caster Wheel(Zinc-plating) – GLOBE Detail:

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

Installation steps of polished casters

1. Prepare casters and tools

Find the screw movable caster that needs to be installed, and correspond to the location that needs to be installed.

2. The installation position has corresponding screw holes

The movable casters must be customized and the corresponding screw holes will be added to the installation position, so that only the casters need to be screwed in and stabilized.

3. The installation location is not standard

Need to tap manually, pay attention to the same diameter as the screw rod, and then screw in the caster, and firmly, and that’s it.

4. Test run

After installation, you need to test it to see where there are problems, and you need to make minor adjustments.

The polished casters only need to be inserted into the corresponding mounting holes to be installed. If there is no mounting hole, you need to manually add the corresponding mounting hole.

8 performance parameters should be paid attention to when choosing casters

There are many performance parameters for casters. When choosing a caster, these 8 parameters are also important indicators. Let’s look at them one by one below.

1. Hardness

It is used to measure the hardness of rubber and other tire and wheel core materials. It is represented by Shore “A” or “D”. Compressive strength During the compression test, the maximum compressive stress that the sample bears, in units of banknotes megapascals.

2. Elongation

Under the action of tensile force, the ratio of the increase in the distance between the marking lines when the sample is broken to the initial gauge length, expressed as a percentage.

3. Impact strength

The ability of the material to withstand the violent impact of free falling heavy objects. It is expressed in inches/pounds, feet/pounds, or punching work at the test temperature.

4. Deformation resistance under heavy pressure

After a long time, the wheel landing site becomes larger and flattened, that is, the test sample bears a certain static pressure load, and then the load is removed after the specified pressure time is over. The height of the wheel landing site after the change of the meter is compared with the original height percentage.

5. Water absorption

The increase in the weight of the test sample. It is expressed as the percentage of the weight of the sample after a specific procedure test to the initial weight.

Six, working temperature

Operating temperature range measured under rated load.

Seven, adhesion

The force required to peel the tire from the bonded wheel core at a speed of 6 inches per minute is calculated in pounds divided by the straight width of the tire.

8. Tensile strength

The force required to break the wheel from the cross section. Divide in pounds by the area (square inches) of the cross-section of the sample.

Product detail pictures:

Related Product Guide:

It adheres for the tenet "Honest, industrious, enterprising, innovative" to develop new products and solutions continuously. It regards shoppers, success as its individual success. Let us produce prosperous future hand in hand for Factory Outlets Metal Caster - Heavy Duty Direction lock Swivel TPR/Endurant/PU Caster Wheel(Zinc-plating) – GLOBE , The product will supply to all over the world, such as: Uruguay, Muscat, Belize, Our company has always insisted on the business principle of "Quality, Honest, and Customer First" by which we have won the trust of clients both from at home and abroad. If you are interested in our products, please do not hesitate to contact us for further information.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!