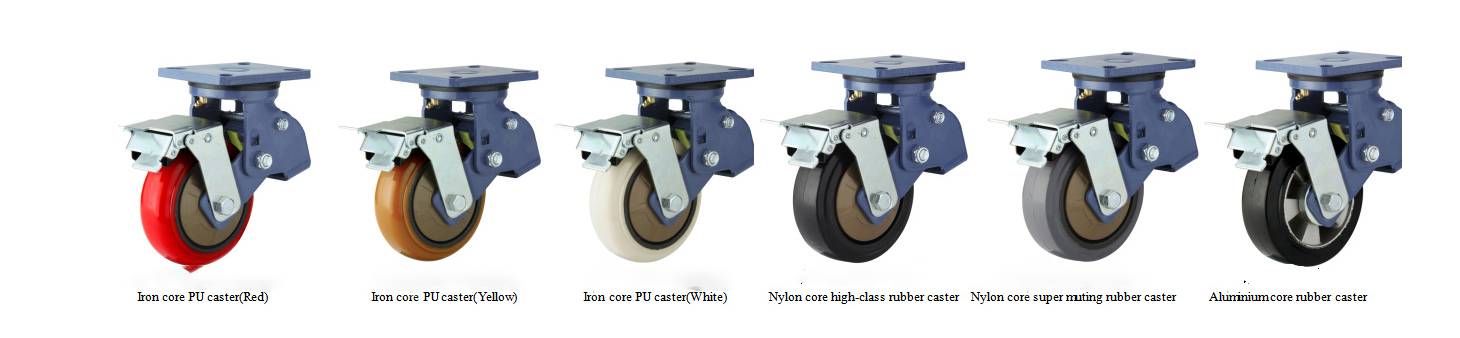

Factory making Solid Nylon Wheel - Extra Heavy Duty Shock absorbing w/brake-Swivel/Rigid PU on Cast Iron Caster(Double Spring)(Baking finish) – GLOBE

Factory making Solid Nylon Wheel - Extra Heavy Duty Shock absorbing w/brake-Swivel/Rigid PU on Cast Iron Caster(Double Spring)(Baking finish) – GLOBE Detail:

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

Analyze caster brackets to help choose high-quality casters

Nowadays, casters are widely used in many industries, such as furniture and furniture, industry, agriculture, logistics handling, warehousing, docks, and national defense technology. But how do we choose industrial casters with so many varieties and specifications? In fact, analyzing the appearance of the bracket is also helpful to purchase high-quality caster products. Here is a detailed introduction of Globe Caster.

1. Analyze from the selection of caster brackets to prevent stealing beams and changing columns.

The regular caster manufacturers use positive steel plates. In order to reduce costs, small factories usually use head and tail plates. The head and tail plates are actually inferior products in the steel plate. The thickness of the head and tail plates is uneven. The price of steel plates also has a big price gap compared with the price of regular plates, and the performance of caster products, such as appearance, load, and other qualities, are also very different.

2. Analyze from the size of the bracket to prevent cutting corners.

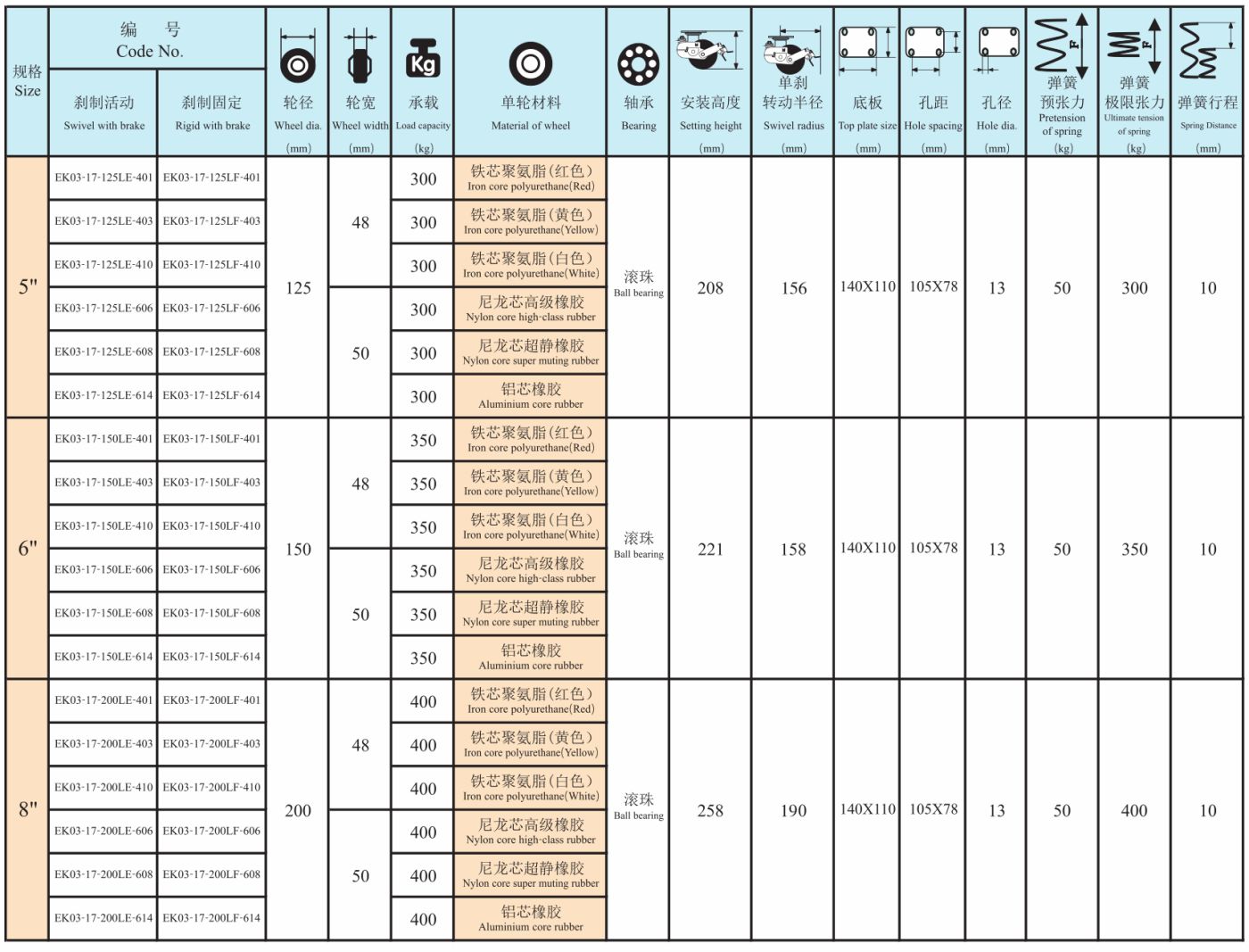

At present, the most frequently used and used casters in the caster market are 4 inches (100mm in diameter), 5 inches (125mm in diameter), 6 inches (150mm in diameter), and 8 inches (200mm in diameter). It was originally produced in accordance with the usage habits of the United States. It is also called American casters. The steel plate thickness is usually 6mm (but due to the Chinese steel plate standard, it is generally a negative tolerance). Therefore, the thickness of the steel plate of the regular caster manufacturer should be It is 5.75mm, and some small caster factories usually use 5mm or even 3.5mm, 4mm steel plates in order to reduce costs, which will inevitably cause the performance and safety factor of the casters to be greatly reduced.

3. From the analysis of the surface treatment of the stent, to prevent overcharging.

The high-quality casters produced by a regular caster factory have beautiful surfaces and no burrs. At the same time, in order to ensure the anti-corrosion treatment of the metal bracket, the caster brackets are generally electro-galvanized (including electro-galvanized white zinc, blue-white zinc, colorful zinc, anti-gold), electrophoresis, Spraying, spraying, dipping, etc. In the market, galvanized brackets are mainly used. In order to improve the adhesion of electro-galvanized casters, regular caster factories generally use shot blasting, and more precise casters will use vibration grinding treatment, which can effectively remove burrs caused by stamping, welding, etc. At the same time, it can better provide the adhesion of the anti-corrosion layer on the surface of the caster.

Although there are many ways to judge the quality of casters, they are always the same. Good materials and reasonable design are the guarantee for the efficient work of casters. You may wish to try to measure the quality of casters from multiple angles.

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, have confidence in the very first and management the advanced" for Factory making Solid Nylon Wheel - Extra Heavy Duty Shock absorbing w/brake-Swivel/Rigid PU on Cast Iron Caster(Double Spring)(Baking finish) – GLOBE , The product will supply to all over the world, such as: Chicago, Maldives, Libya, Regarding quality as survival, prestige as guarantee, innovation as motive force, development along with advanced technology, our group hopes to make progress together with you and make untiring efforts for the bright future of this industry.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.