Factory made hot-sale China Elevator Castors - ED3 Series-Top plate type-Swivel/Rigid – GLOBE

Factory made hot-sale China Elevator Castors - ED3 Series-Top plate type-Swivel/Rigid – GLOBE Detail:

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

How to consider the appropriate weight of industrial casters

The choice of industrial casters must first consider the site and environment you use, and choose a wheel large enough to accommodate the cracks in the scene. Also consider the size of the road surface, obstacles and other factors; each wheel adapts to different working environments, and choose the right one to adapt to the special environment. The choice of industrial casters depends on the carrying capacity, which determines the weight of the load, the size of the wheel, and also affects the rotatability of the industrial casters. Ball bearings are suitable for heavier load requirements of more than 180 kg.

The choice of industrial casters ultimately depends on its flexibility of rotation and temperature limit. The larger the wheel, the more labor-saving. The ball bearing can carry heavier load. The ball bearing can rotate more flexibly but bears less load; severe cold and heat affect many wheels. It may cause trouble. If the casters use special green grease, the casters can be suitable for high temperatures from -40°C to 165°C.

Industrial casters mainly refer to a caster product used in factories or mechanical equipment. It can be made of high-grade imported reinforced nylon (PA6), super polyurethane, and rubber. The overall product has high impact resistance and strength.

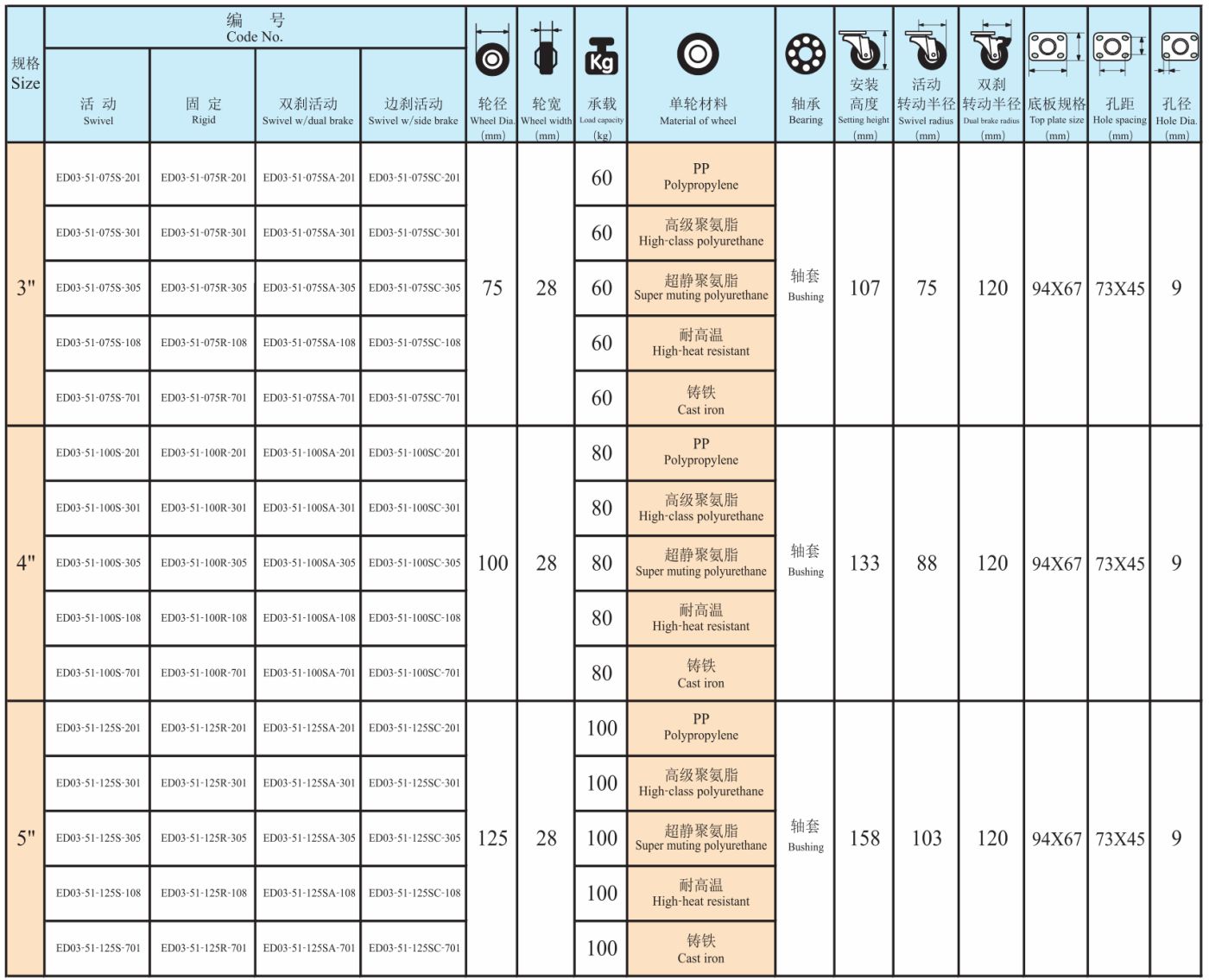

Product detail pictures:

Related Product Guide:

Every single member from our large efficiency revenue team values customers' wants and company communication for Factory made hot-sale China Elevator Castors - ED3 Series-Top plate type-Swivel/Rigid – GLOBE , The product will supply to all over the world, such as: Rwanda, Wellington, Ethiopia, To work with an excellent items manufacturer, our company is your best choice. Warmly welcome you and opening up the boundaries of communication. We are the ideal partner of your business development and look forward to your sincere cooperation.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!