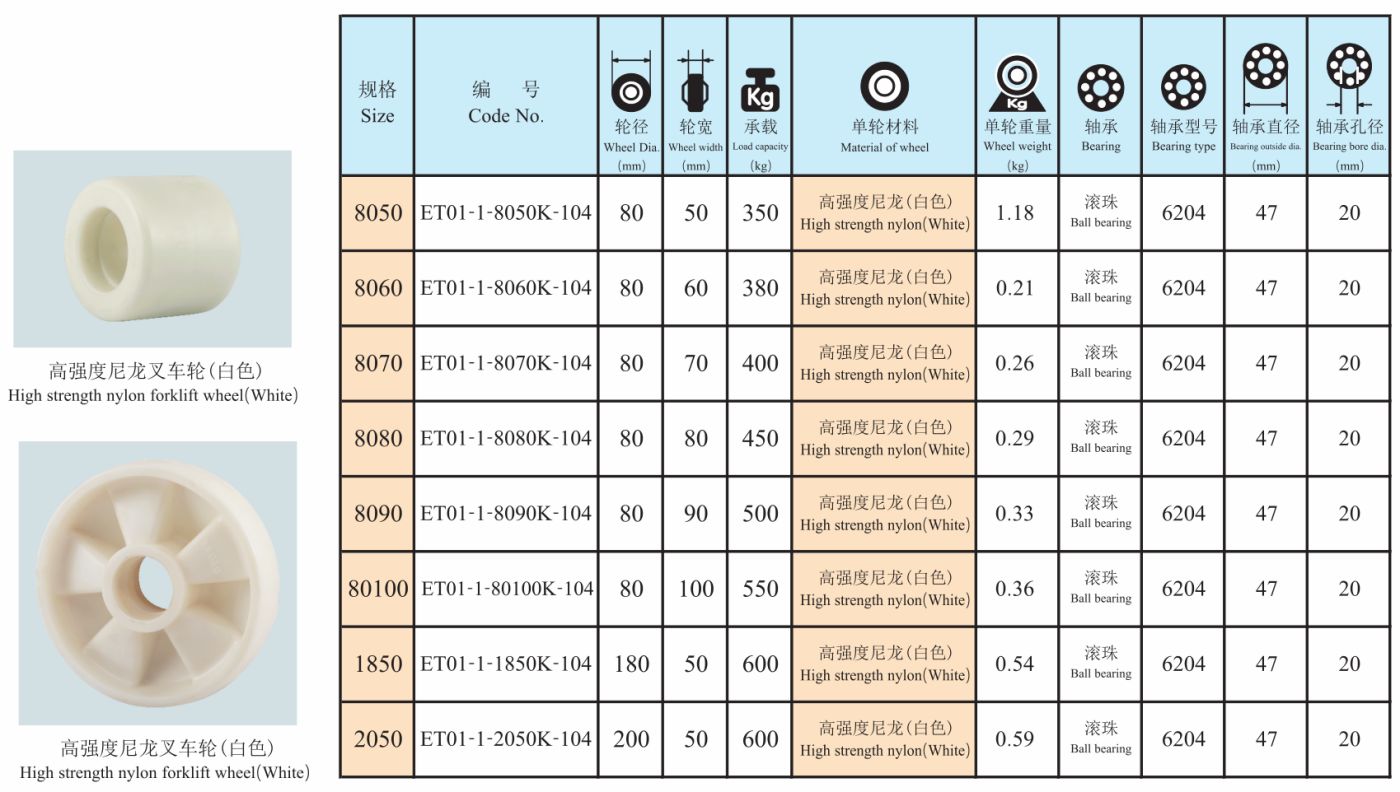

High Strength Nylon Forklift Wheels (White) Wheel ET1 Series High strength nylon forklift wheel(white)(flat)

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

Damping casters can adjust uneven ground because of their special structure. Rubber shock-absorbing casters have rubber as the buffer material; spring shock-absorbing casters have springs as the buffer material; there are also some casters that have both rubber and springs as the buffer material.

Shock-absorbing casters play an extremely important role in industry, and are measures to ease the impact of machinery in mechanical vibration. There are various impact problems in the project. The landing of aircraft, the rapid reciprocating movement of machine tool components, and the lifting or falling of packaging materials will all cause impacts on machinery and foundations. Under the action of impact force, the parts of the machinery will generate great dynamic stress, which may cause damage, and the surrounding machinery and buildings may also be harmed. Therefore, all unnecessary impacts should be buffered or isolated in mechanical engineering. For example, cushioning materials must be placed at the bottom of the anvil of a forging machine; to ensure that precision machinery or instruments are not damaged during lifting and transportation, reliable cushioning measures should be taken. Cushioning is different from vibration isolation and damping. It uses a cushioning device to absorb the impact energy and then converts it into heat, or releases it gently to extend the time of speed change, so as to achieve the purpose of minimizing the impact of mechanical equipment. .

During the operation of the shock-absorbing caster, the kinetic energy of the vibration of the object is stored by the elastic body as its own elastic potential energy. The increase or decrease of the elastic potential energy ensures the safety of the loaded object.

The main difference between Globe Caster shock-absorbing casters and ordinary casters is its shock-absorbing device:

1. Start easily.

Globe Caster shock-absorbing casters use high-quality iron core outsourcing polyurethane wheels. Polyurethane has good flexibility and abrasion resistance. When installed on an equipment vehicle, it can not only reduce noise, but also has a small starting force.

2. Resistant to high load-bearing steering.

The caster steering ball disc adopts a heat treatment process to heat the bottom plate and the large elastic cover that carry the steel balls, which can greatly improve its hardness and toughness, and can better steer during the high-load traction process, greatly reducing unnecessary wear and noise. The workshop reduces costs. And provide a quiet production environment.

3. Shock absorption performance.

The spring casters use high-quality shock-resistant and shock-resistant springs to make the wheels turn more flexible and easy, greatly improve the force performance, protect the wheels and brackets, and avoid damage to the casters and even machinery or goods due to vibration when the wheels are walking on uneven ground.