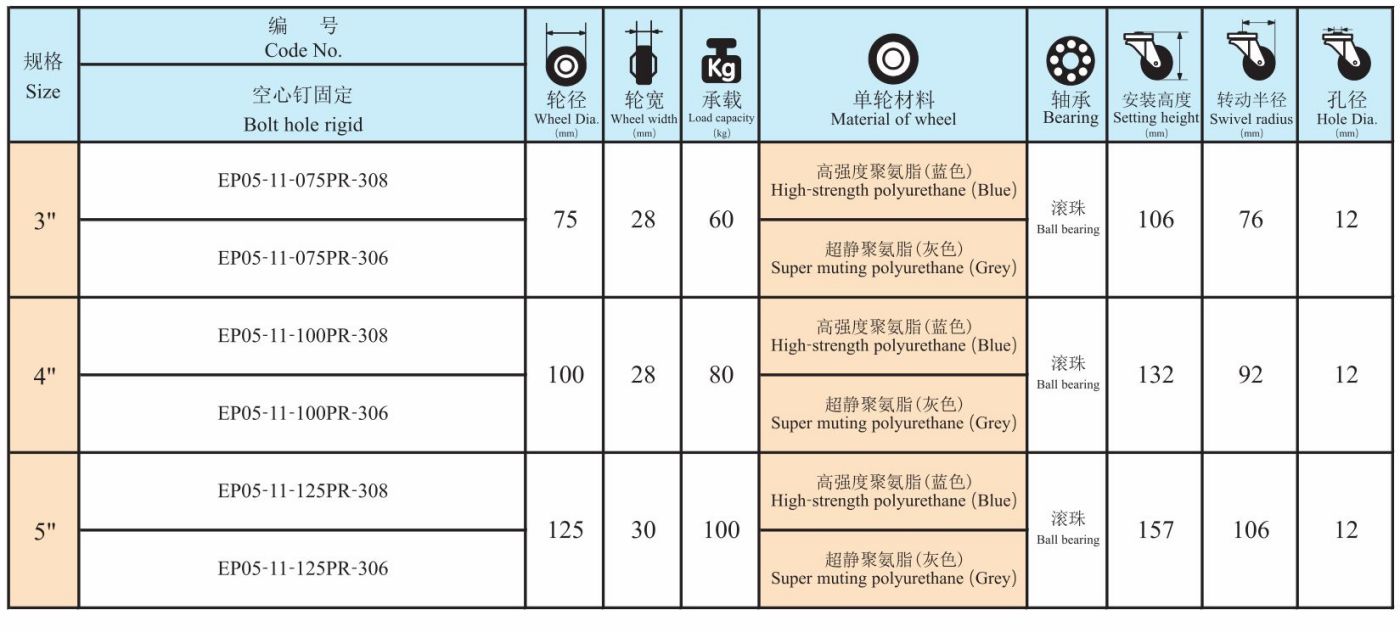

OEM China Manufacturer Rubber TPR Wheel Shopping Cart Trolley Caster EP5 Series Bolt hole type rigid polyurethane caster

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing:

Workshop:

Every industry has a fixed terminology, and the caster industry is no exception. Familiar with the professional terminology of the caster industry, it will be of great help to you in the future to buy high-quality casters. Globe Caster summarizes the following common caster industry terminology for you.

1. Device height: The device height of the caster refers to the far vertical distance from the bottom of the caster and the wheel. Refers to the vertical distance from the ground to the location of the equipment.

2. Bracket steering center distance: refers to the horizontal distance from the vertical line of the center rivet to the center of the wheel core.

3. Driving load: The load-bearing capacity of casters when they are moving, also called dynamic load. The dynamic load of the caster varies due to the implementation of the specifications and the factory's test methods. It is also different due to the different materials of the wheels. The key is whether the structure and quality of the bracket can resist impact and shock.

4. Impact load: the instantaneous load-bearing capacity of the caster when the equipment is impacted or shaken by the load.

5. Turning radius: The proper spacing enables the casters to turn 360 degrees. Whether the turning radius is reasonable or not directly affects the service life of the caster, which refers to the horizontal distance from the vertical line of the center rivet to the outer edge of the tire.

6. Static load: The static load should be at least twice the impact load. The weight that a caster can bear in a static state. The static load should generally be twice the exercise load.

7. driving flexibility: on a stable ground, the factors that affect the flexibility of the casters are: the structure of the support and the selection of the support steel, the size of the wheel, the type of the wheel, the bearing, etc. The larger the wheels, the better the driving flexibility. Hard, narrow wheels require less effort than flat-edged, soft wheels. But on uneven ground, the soft wheels save effort. But on uneven ground, soft wheels can better maintain the equipment and absorb shocks.

8. Turning: Too short a turning radius will increase the difficulty of turning. Hard and narrow wheels are easier to turn than soft and wide wheels. The turning radius is an important parameter of wheel rotation. Too large will cause the wheel to shake and shorten the life.

Through the above introduction, you should have a preliminary understanding of the proprietary terminology of the caster industry. Globe Caster tells you a little trick. When purchasing casters, using professional terminology will help you better communicate with the manufacturer. We will continue to update our expertise in the caster industry and look forward to your attention.