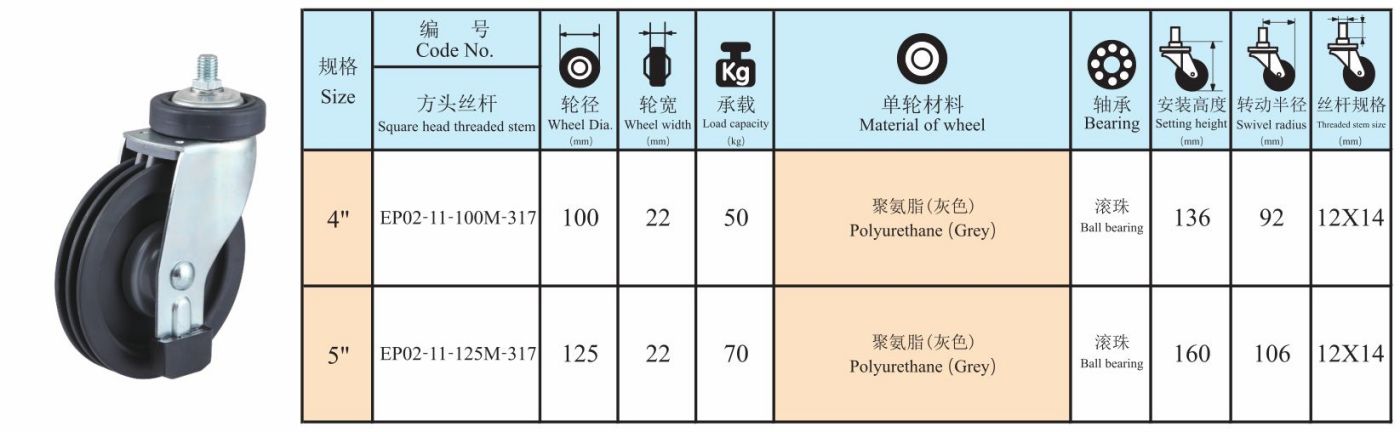

China Factory Price 5 Inch Fixed Rigid Shopping Cart Casters Trolley Wheel Double Dish PP PU Elevator Caster Wheel EP2 Series Square head threaded stem type three slices elevator castor

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

Casters have been widely used and are easy to see in life, but should we judge whether the casters produced are qualified? Below, Globe Caster will introduce the test methods and requirements of casters in detail.

1. Impact test

Any item due to transportation, use, storage and other conditions may produce impact and vibration, which will make the product unable to be used normally for a certain period of time. Furniture is often vulnerable to impact due to its large size and weight. Casters located at the bottom determine whether the furniture is stable or not. It should have good impact resistance.

The impact resistance test method in the European caster test standard is: install the caster vertically on the ground test platform, and make the weight of 5KG (±2%) fall freely from the position where the height is 200mm, the allowable deviation is ±3mm Impact on the side of the caster wheel, if it is two wheels, the two wheels should impact at the same time. During the whole experiment, no part of the caster is allowed to separate. And after the experiment is completed, the rolling, pivoting or braking function of the casters should not be damaged.

2. Resistance performance test

When testing this performance, the caster should be kept dry and clean. Place the caster on a metal plate insulated from the ground, keep the wheel edge in contact with the metal plate, and load 5% to 10% of its nominal load on the caster. Use an insulation resistance tester (the nominal open circuit voltage is 500V, the measured resistance value fluctuates within 10% and the loss on the product does not exceed 3W) to measure the resistance value between the caster and the metal plate. For conductive casters, the resistance value should not be greater than 104 ohms, while the resistance of antistatic casters should be between 105 ohms and 107 ohms.

3. Static load test

Casters should always run steadily on the ground, but that is almost a purely theoretical state. On uneven surfaces, or when crossing thresholds, tracks, and pits, the casters will leave the ground briefly. So when they are suddenly overloaded or when three of the four casters touch the ground, they must carry the load of the entire furniture.

The test process of the static load of the caster in the European standard is to fix the caster on a horizontal and smooth steel test platform with screws, apply a force of 800N along the center of gravity of the caster to maintain 24H, and check the condition of the caster after removing the force for 24 hours. The measured deformation of the caster does not exceed 3% of the wheel diameter, and after the experiment is completed, the caster's rolling, pivoting or braking function is not damaged.

The above three points summarized by Globe Caster are for the reference of our customers, and hope to help everyone choose the qualified casters correctly. If you have any questions, we sincerely welcome everyone to come to consult!