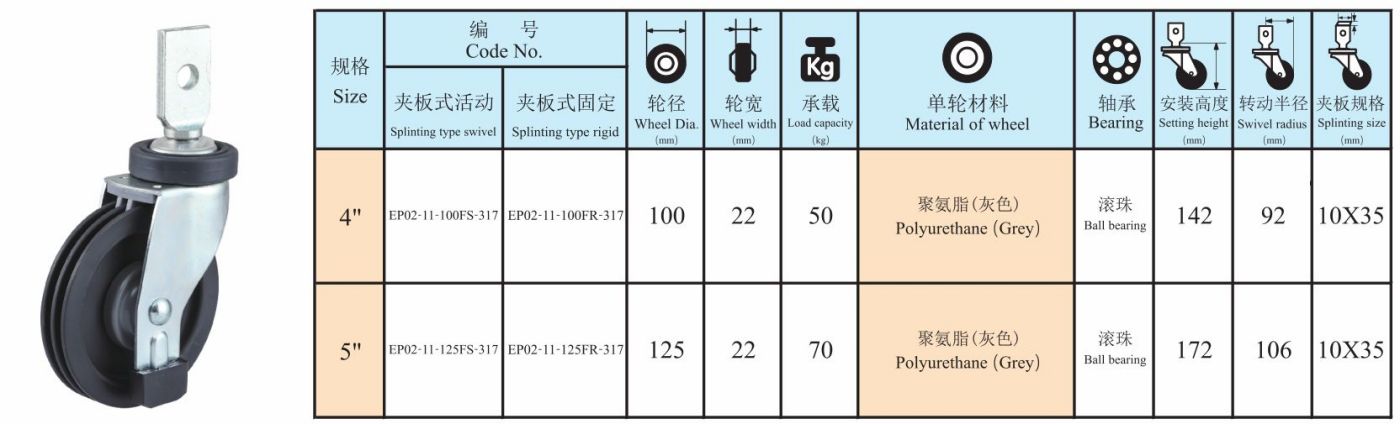

Shopping Cart PU Supermarket Caster Trolley Wheel EP2 Series Splint type Swivel Rigid three elevator castor

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

Industrial casters mainly refer to a caster product used in factories or mechanical equipment, which has high impact resistance and strength as a whole. Then, in the process of choosing casters, how to grasp its size is a problem that our customers are concerned about. Below Globe Caster will show you how to choose suitable size industrial casters.

First of all, we must choose the right caster wheel material: usually the wheel materials are nylon, rubber, polyurethane, elastic rubber, polyurethane core, cast iron, plastic, etc. Polyurethane wheels can meet your handling requirements regardless of whether they are running on indoor or outdoor ground; elastic rubber wheels can be suitable for hotels, medical equipment, wooden floors, tiled floors and other grounds that require low noise and quiet when walking; nylon wheels, The iron wheel is suitable for places where the ground is uneven or there are iron filings and other materials on the ground.

How to calculate the load-bearing weight of casters: In order to be able to calculate the required load-bearing capacity of various casters, it is necessary to know the weight of the transport equipment, the heavy load, and the number of wheels and casters used.

The choice of caster diameter: Generally speaking, the larger the diameter of the wheel, the easier it is to push and the greater the carrying capacity. At the same time, it can protect the ground from damage. The choice of wheel diameter must first consider the weight of the load and the starting thrust of the truck under load.

Ensure the flexibility of wheel rotation: the larger the wheel, the less effort it will turn. The needle bearing can carry heavier loads and has greater resistance during rotation; the wheel is equipped with high-quality ball bearings, which can carry heavier loads and rotate more easily , Flexible and quiet.

The above introduction is how to choose suitable size industrial caster products, I hope it will be helpful to you. You are welcome to buy Globe Caster products, we always take it as our responsibility to provide customers with high-quality products, and look forward to your visit !