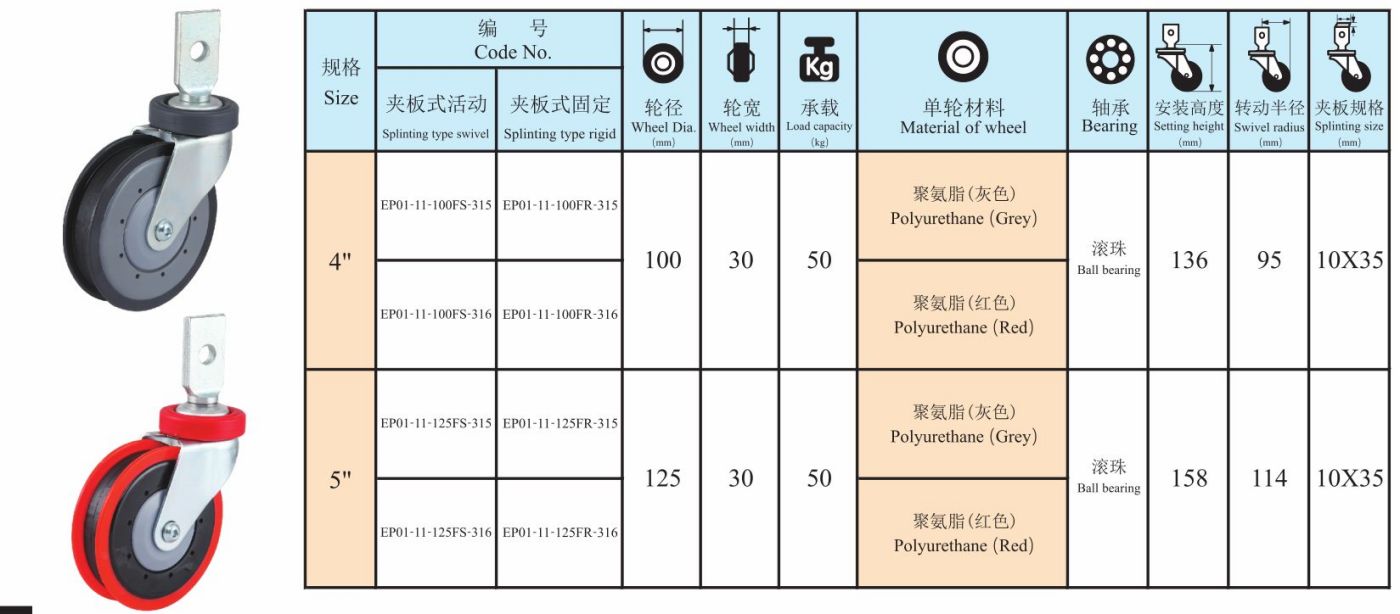

5 Inch Swivel Elevator Shopping Cart Caster Supermarket Trolley Wheel EP1 Series-Splinting type Swivel/Rigid two slices elevator castor

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

At present, the caster market has many varieties and specifications, which dazzles users, and the quality of casters is also uneven. In order to allow users to choose high-quality caster products, Globe Caster has compiled a method for identifying the quality of casters from the appearance.

1. From the appearance analysis of the caster packaging

Generally speaking, regular caster factories use cartons or pallets to package and transport the casters, marked with obvious marks (including the product name of the caster, manufacturer's address, telephone, etc.) to effectively prevent the caster from being damaged during transportation. However, because small factories have not formed mass production or in order to save costs, they usually use woven bags for packaging, which cannot ensure that the caster products are not damaged during transportation.

2. From the appearance analysis of the caster bracket

- Analyze from the selection of caster brackets to prevent stealing beams and changing columns.

The brackets of the casters generally use injection molding brackets or metal brackets. The thickness of the metal brackets of the casters ranges from 1mm or even less to 30mm. The regular caster manufacturers use positive plate steel plates. In order to reduce costs, small factories usually use head and tail plates. The head and tail plates are actually the inferior products of the steel plates. The thickness of the head and tail plates is uneven.

- Analyze the size of the caster bracket to prevent cutting corners.

The thickness of the steel plate of the regular caster manufacturer should be 5.75mm, and some small caster manufacturers usually use 5mm or even 3.5mm steel plate in order to reduce the cost, which greatly reduces the performance and safety factor of the caster in use.

3. from the appearance analysis of caster wheels

Casters are used to move, whether they are injection-molded plastic wheels or processed metal caster wheels, so the caster wheels must be round or spherical. This is the most basic principle and must not be out of round. The surface of the caster wheels should be smooth, free from bumps, uniform in color, and no obvious color difference.

4.from the work performance analysis of casters

For high-quality casters, when the top plate rotates, each steel ball should be able to contact the steel runway surface. The rotation is smooth and there is no obvious resistance. When the wheels rotate, they should rotate flexibly without obvious up and down jumps.

The above four points summarized by Globe Caster are for reference of our customers, hoping to help you choose the most suitable caster correctly. If you have any questions, please come to consult !