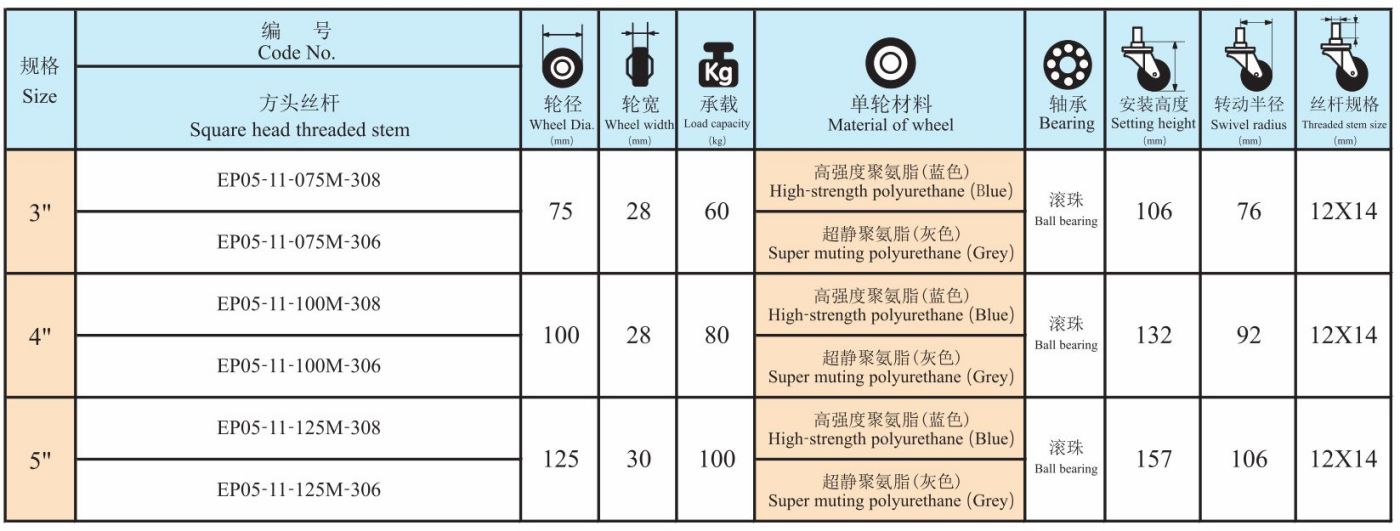

OEM China Manufacturer Rubber TPR Wheel Shopping Cart Trolley Caster EP 5 Series Square head threaded stem polyurethane caster

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

Universal wheels are more and more widely used in our daily production and life, and their daily maintenance has gradually become the focus of users' attention. Today Globe Caster is here to teach you a few points of attention when using universal wheels, which makes the universal wheels more durable.

1. Avoid overloading: When using the universal wheel, the user should recognize the load-bearing weight of the universal wheel and its supporting products, and choose a universal wheel with a suitable load for use. Pre-estimate the weight of the object to be carried before use. The selected universal wheel and its supporting products should carry more than 1.5 times of the weight.

2. Choose universal wheels of different materials for different places of use: Universal wheels of different materials have different physical and chemical properties. The different materials of the universal wheel and the different environment of the use place will lead to different service life of the universal wheel. When using the universal wheel, the user should be aware of the suitable place to use the universal wheel to avoid unnecessary losses.

3. Effective maintenance of casters: The user should regularly maintain the running parts of the casters. Maintenance is divided into three aspects: adding lubricating oil, removing entanglements from the running parts, and preventing rust. The details are as follows:

1. Lubricating oil should be added to the running parts of the steel ball of the support of the universal wheel and the running parts of the wheel bearings on a regular basis.

2. Regularly clean the windings or thread ends of the steel ball winding parts of the support of the universal wheel and the cloud-mounted parts of the wheel bearings;

3. Most of the universal wheel brackets are made of metal. Anti-corrosion is very important to the service life of the universal wheel. To prevent the universal wheel bracket from rusting, you can apply anti-rust paint and anti-rust oil on a regular basis.

The above are the three points that Globe Caster summarized for you to make the universal wheel more durable. Only by standardizing the use of universal wheels and paying attention to the daily maintenance of the universal wheels can the service life of the universal wheels be prolonged and the functions of the universal wheels can be maximized.