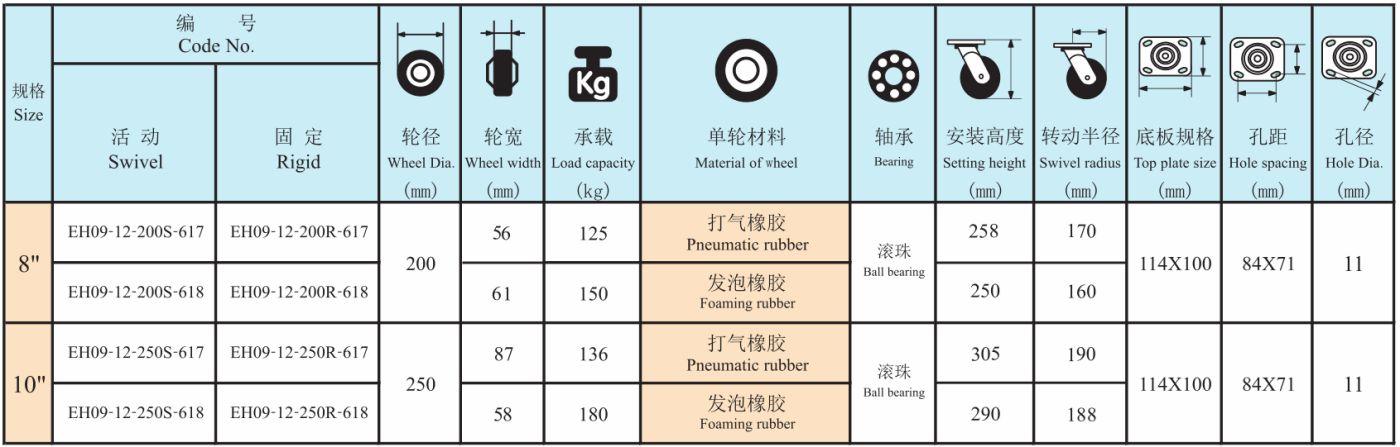

Industrial Heavy Duty Pneumatic Rubber Top plate Swivel/Rigid Caster(Colored-plating)

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

In the application of universal wheels, wear is an aspect worth paying attention to. According to the production and research experience of Globe Caster, in daily operation, the wear inspection of universal wheels can start from three aspects.

1. Swivel casters loose or stuck wheels can also cause "flat points", proper maintenance and inspection, especially checking the tightness of bolts, the amount of lubricating oil, replacement of damaged casters can enhance the rolling performance and flexible rotation of the equipment sex.

2. Severe damage or looseness of rubber casters may lead to unstable rolling, air leakage, abnormal load, and damage to the bottom plate, etc. Timely replacement of the damaged casters and bearings can reduce the cost loss caused by the downtime caused by the damage of the casters.

3. Check whether the wheel bearings are damaged. If the parts are not damaged, they can be reassembled and used again. If the wheel is often entangled by debris, it is recommended to install an anti-wrap cover to avoid it.

Reducing wear is one aspect of the maintenance of the universal wheel. On the other hand, we also start from the ground conditions. For some reasons, the ground conditions are really bad. After using the universal wheel, remember to check the wear and tear and deal with it accordingly.

Casters belong to the general accessories category of hardware and are widely used in turnover transport vehicles in industries such as industry, ship terminals, medical care, and supermarkets. The development of a city is inseparable from casters, and the wide range of applications of casters reflects the level of civilization of a city.

Overall introduction of casters:

Casters are collectively referred to as movable and directional casters. Movable casters are what we call universal wheels, and its mechanism allows 360-degree rotation. Fixed casters are also called directional wheels, which have no rotating structure and cannot be rotated. Usually two kinds of casters are used together. For example, the structure of a trolley has two fixed wheels on the front and two movable universal wheels on the back that are close to the push armrest.

Classification of casters:

According to the application industry classification, it is mainly divided into industrial casters, medical casters, supermarket casters, furniture casters, etc.

Their difference:

Industrial casters: A caster product mainly used in factories or mechanical equipment. It can choose high-grade imported reinforced nylon (PA), polyurethane, and rubber single-wheel products with high overall impact and strength.

Medical silent casters

Medical casters: In order to meet the requirements of hospitals, such as light operation, flexible steering, large elasticity, special ultra-quiet, abrasion resistance, anti-winding and chemical characteristics, special casters.

Supermarket casters: casters specially developed to meet the mobile needs of supermarket shelves and the lightweight and flexible characteristics of shopping carts.

Furniture casters: A type of special rubber wheels mainly produced to meet the needs of furniture requiring a low center of gravity and high load-bearing capacity.

Classified by material:

According to the material, it is mainly divided into thermoplastic polyurethane, polypropylene (pp), nylon (PA), thermoplastic rubber, and polyvinyl chloride.

Thermoplastic polyurethane features: recyclable thermoplastic polyurethane tire polypropylene copolymer wheel center, is an ideal choice for both load requirements and ground protection, low noise, wear resistance, impact resistance, spinning grease, mineral oil and some acids The normal operating speed is 4km/h.

Polypropylene (pp) features: the tire core and tread of recyclable polypropylene copolymer are suitable for light and heavy duty. It is easy to operate and save manual labor. It is resistant to deformation under static load, high cost performance, good chemical resistance, moderate The impact-resistant normal operating speed is 4km/h.

Nylon (PA) features: high-quality nylon tire core and tread, light weight, low mechanical resistance, flexible rotation, manual and mechanical use more labor-saving, use of equipment working in humid environments, anti-grease, crude oil, salt, and some acidic substances, Environmentally friendly materials, the normal operating speed can reach 4km/h.

Thermoplastic rubber features: excellent tensile resistance, the highest tensile strength. Long-term temperature resistance over 70 ℃, low temperature environment performance, good bending properties at -60 ℃, good electrical insulation, anti-skid, resistance Abrasion, weather resistance and general chemicals.

Polyvinyl chloride features: flame retardant, it is widely used in fire protection applications, it is not easy to be corroded by acid and alkali and is more heat resistant. It has good tensile, bending, compressive and impact resistance.

Divided by installation method:

Floor type: including floor type universal wheels and floor type brake wheels for various loads.

Screw type: Including screw type universal wheels and screw type brake wheels are mostly used for light and medium loads.

Plug-in rod type: Including rod-in universal wheel and rod-in brake wheel are mostly used for light and medium-duty loads.

Bracket material: Carbon steel is generally used as the material, which can be electroplated, such as zinc plating, copper plating, nickel plating, chrome plating, spraying, etc. Stainless steel is also used, and our company is mainly made of stainless steel and cast iron.

How to choose casters:

There are many types of casters, which are different in size, model, and tire surface. Choosing the right caster depends on the following conditions:

Size: Generally, the larger the diameter, the more labor-saving and the more obstacles it will be. The greater the load capacity and the better protection of the ground from damage. The choice of wheel diameter should first consider the weight to be carried and the starting thrust of the truck under the load. To decide.

Site environment used:

The working environment contains chemicals, blood, grease, engine oil, salt and other substances.

Special requirements: silence, shock absorption, various special climates, such as humidity, high temperature or severe cold. Safety requirements for impact resistance and collision driving.

Precautions:

1. Avoid being overweight.

2. Do not offset.

3. Regular maintenance, such as regular oiling, timely inspection of screws.