Caster Manufacturer Medium Duty Industrial Trolley PU Castor

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

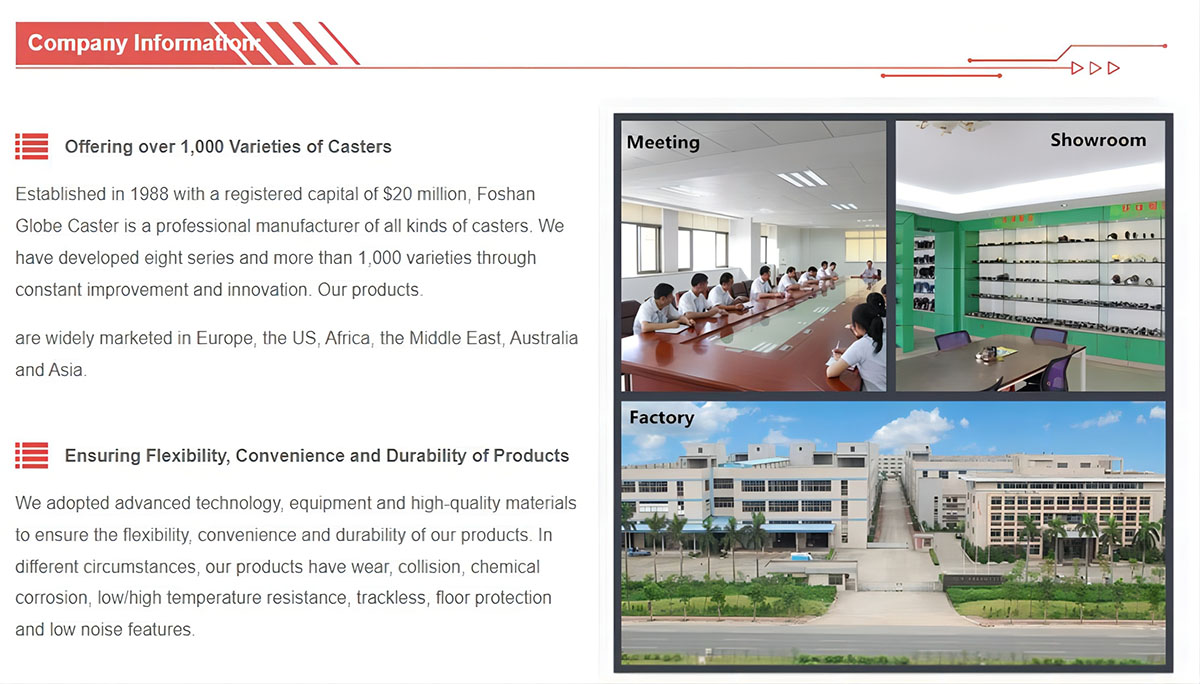

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing:

Workshop:

1. Compound of thermoplastic elastomer TPE | TPR has the advantages of easy machining and forming, excellent wear resistance and elasticity, shock absorption and low noise. It has become an important raw material for the production of bicycles and utility bicycles.

2. Common universal wheels such as shelf wheels, trolley wheels, etc. These are composite molded parts of hard plastic (such as PP, PA) and soft plastic (such as TPR, TPE, PU, EVA, TPU) ... Hard plastic plays a key role as the wheel frame material, while soft plastic plays the role of slip resistance, shock absorption and noise reduction.

3. Currently, hard plastics in the production of universal wheels are mainly made of copolymerized polypropylene and some of them are made of polyamide. Soft plastics are made from TPE and the market demand for TPR is a major contributor. Machining and shaping of this type of wheel is usually done in a two-step injection molding process. That is, the first step is to introduce hard plastic parts made of polypropylene or polyamide; The second step is to place the molded hard plastic parts in another mold set and fix the position, then apply soft TPE plastic, TPR glue to where the hard plastic part needs to be coated.