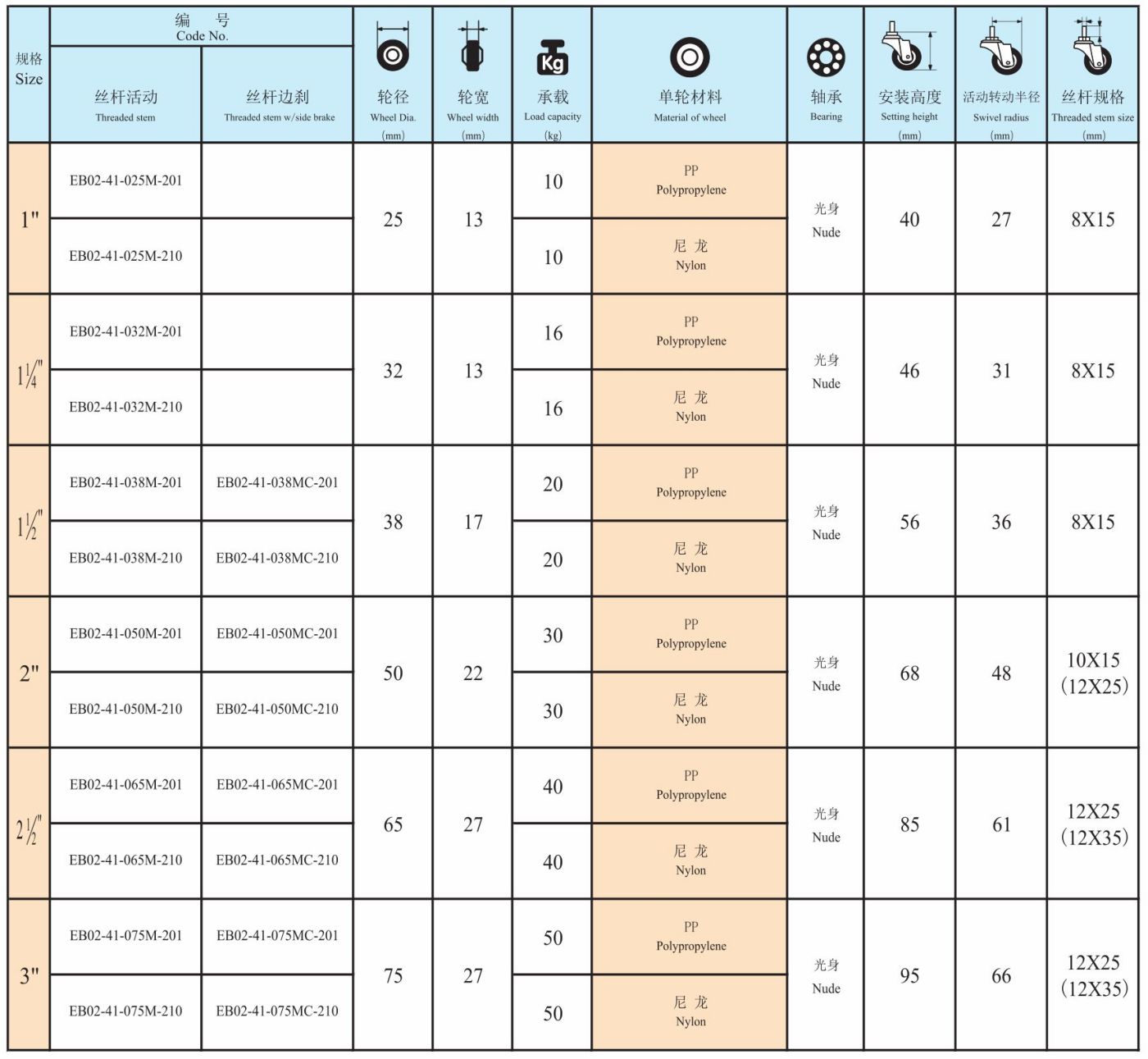

Light Duty PU Wheel Rotating Top Plate Type Equipment Caster EB2 Series-Threaded stem type(Zinc plating)

PP caster

Nylon caster

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

Shock-absorbing casters now bring great convenience to our production and life, so how much do you know about the materials of shock-absorbing casters? Below we briefly introduce the materials and functional characteristics of the lower shock-absorbing casters: The high-quality rubber shock-absorbing casters produced by Globe Caster are made of high-quality polyurethane iron core polyurethane casters, which have good toughness and elasticity and wear resistance. High-tech polyurethane package The iron core casters have the characteristics of anti-fouling, oil resistance, wear resistance and high load capacity. The shock-absorbing casters have good sealing, dust-proof and anti-winding performance. Dust-proof and anti-winding, to suit the choice and requirements of different environments.

Globe Caster's shock-absorbing wheels are made of high-quality polyurethane, with excellent toughness, elasticity and abrasion resistance, and are highly praised by consumers. Let’s take a look at the excellent performance of the shock-absorbing wheels:

1. Shock absorption effect: single/double springs are used, the cushioning effect is more obvious;

2. Rotating parts: larger bottom plate and steel ball plate, double-layer steel ball track, steel ball plate bottom plate are all heat-treated to increase the strength, and better increase the load-bearing strength and rotation flexibility of the casters;

3. Bearings: The bearings are more durable, and the dust cover is installed to effectively protect the bearings and prolong the service life;

4. Thickness of iron plate: National standard 8mm; bottom plate and large bullet cover adopt S-45C hot-rolling and forging process, and heat treatment is carried out to increase the strength;

5. Bracket structure: The bottom plate of the bracket adopts a double-sided fully welded structure, which is more reliable in use;

6. Surface treatment: environmental protection galvanized, neutral salt spray test for 24 hours without white embroidery;

7. Wheel material: The wheel is made of reinforced cast iron solid wheel, and the outer skin is cast-type high-grade wear-resistant polyurethane elastomer;

8. Wheel color: red, beige, blue, gray, etc. can be customized according to customer requirements.

Application area

1. Carrying equipment with large load capacity that needs shock absorption;

2. Carrying equipment for auto parts;

3. Other heavy-duty transportation requires buffering and shock-absorbing handling equipment.

Over the years, Globe Caster has always been technology-based and market-oriented. With its superb technology, craftsmanship and efficient products, and perfect after-sales service, it has won the trust of users and has grown in the product market.

The shock-absorbing casters have good sealing, dust-proof, waterproof and anti-winding performance. The casters are sealed and anti-winding. The bead plate adopts a sealing ring, which is very dustproof, waterproof and anti-winding, which is suitable for the selection and requirements of different environments. Easy-to-start shock-absorbing casters have the characteristics of low starting power when they are installed on equipment vehicles. High load capacity The ultra-quiet damping wave plate adopts a flat surface, which can better prevent the shaking of the feet and wheels during the high-speed towing process, which greatly reduces the noise and provides a quiet production environment for the production workshop.