Chinese Professional Waste Bin Wheel - Polyurethane Caster Stainless steel Shopping Trolley Bolt Hole PU Wheel – GLOBE

Chinese Professional Waste Bin Wheel - Polyurethane Caster Stainless steel Shopping Trolley Bolt Hole PU Wheel – GLOBE Detail:

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

Five ways to ensure the quality of casters

Simple creation and invention are usually very important, and casters also have this characteristic. At the same time, the development trend level of a big city is usually positively correlated with the application of casters. The usage rate of casters in big cities is very high.

1. Reciprocating damage test:

The reciprocating damage experiment of casters simulates the flipping of casters in daily applications. The caster manufacturer should carry out a two-point experiment on whether there are obstructions. During the whole experiment, no casters or other components are allowed to get rid of, and each caster is completed when the experiment is completed. It should be able to promote all its normal functions. After the experiment is carried out, the rotation around the axis or the effect of the braking system cannot be destroyed.

2. Accurate measurement of flip friction resistance and rotation friction resistance:

When the caster angle of the kingpin moves or its driving direction is manipulated, the force must be transmitted to the caster angle of the kingpin according to the object and get rid of the frictional resistance. Friction resistance lies in: load carrying capacity, wheel diameter, wheel material, wheel surface appearance and electromagnetic oscillation of continuous casting, etc.

3. If the tire rubber is seriously damaged or loosened, it is very likely to cause instability, steam leakage, abnormal load, damage to the bottom plate, etc. The caster manufacturer immediately removes the damaged tires and rolling bearings, which can reduce the cost caused by the suspension of production due to the damage of the caster. Fee damage.

4. After regularly inspecting and repairing the wheels, make sure whether the anchor bolts and nuts are tightened, and try to apply locknuts or locknuts on all anchor bolts. If the anchor bolts are loose, they should be tightened immediately. If the wheel in the fixed bracket becomes loose, the wheel will be destroyed or unable to rotate.

5. Load test:

Casters should run smoothly on the road from start to finish, but this is basically a purely theoretical situation. Casters leave the temporary jagged surface of the pavement, or go beyond thresholds, rails and pits. Therefore, when they are suddenly overweight or three-quarters of the casters hit the ground, they must install all the furniture.

In short, the above are some methods to ensure the quality of the casters. Among them, the inspection equipment to ensure the quality of the casters is very important. For our consumers, often only the appearance of the casters can be seen, so the quality of the casters appears to be good or bad from the appearance of the casters. More practical. Generally, industrial casters are more durable than other casters and have a longer practical life!

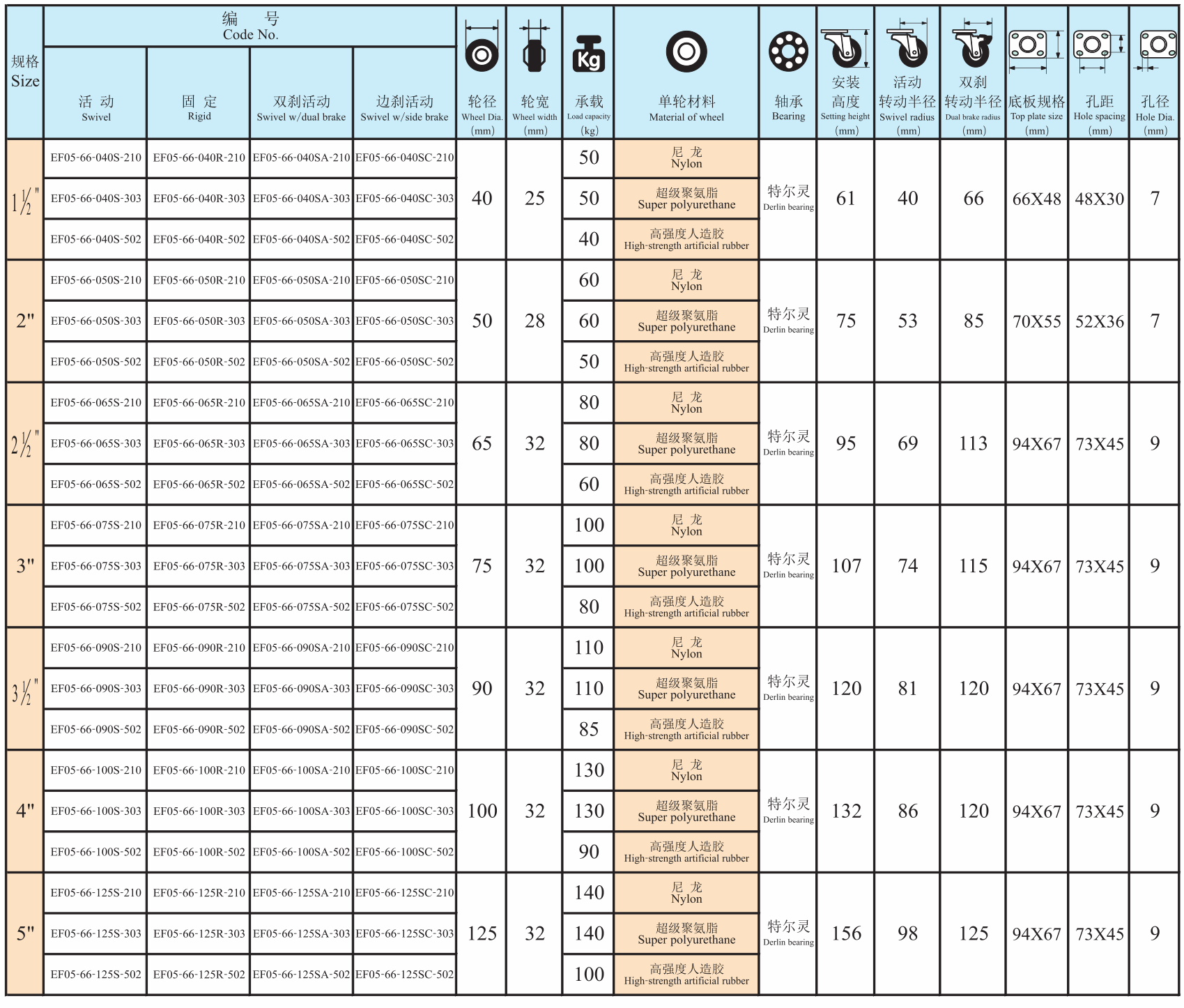

Product detail pictures:

Related Product Guide:

Our mission will be to become an innovative supplier of high-tech digital and communication devices by furnishing benefit added structure, world-class manufacturing, and service capabilities for Chinese Professional Waste Bin Wheel - Polyurethane Caster Stainless steel Shopping Trolley Bolt Hole PU Wheel – GLOBE , The product will supply to all over the world, such as: Greece, azerbaijan, Denmark, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.