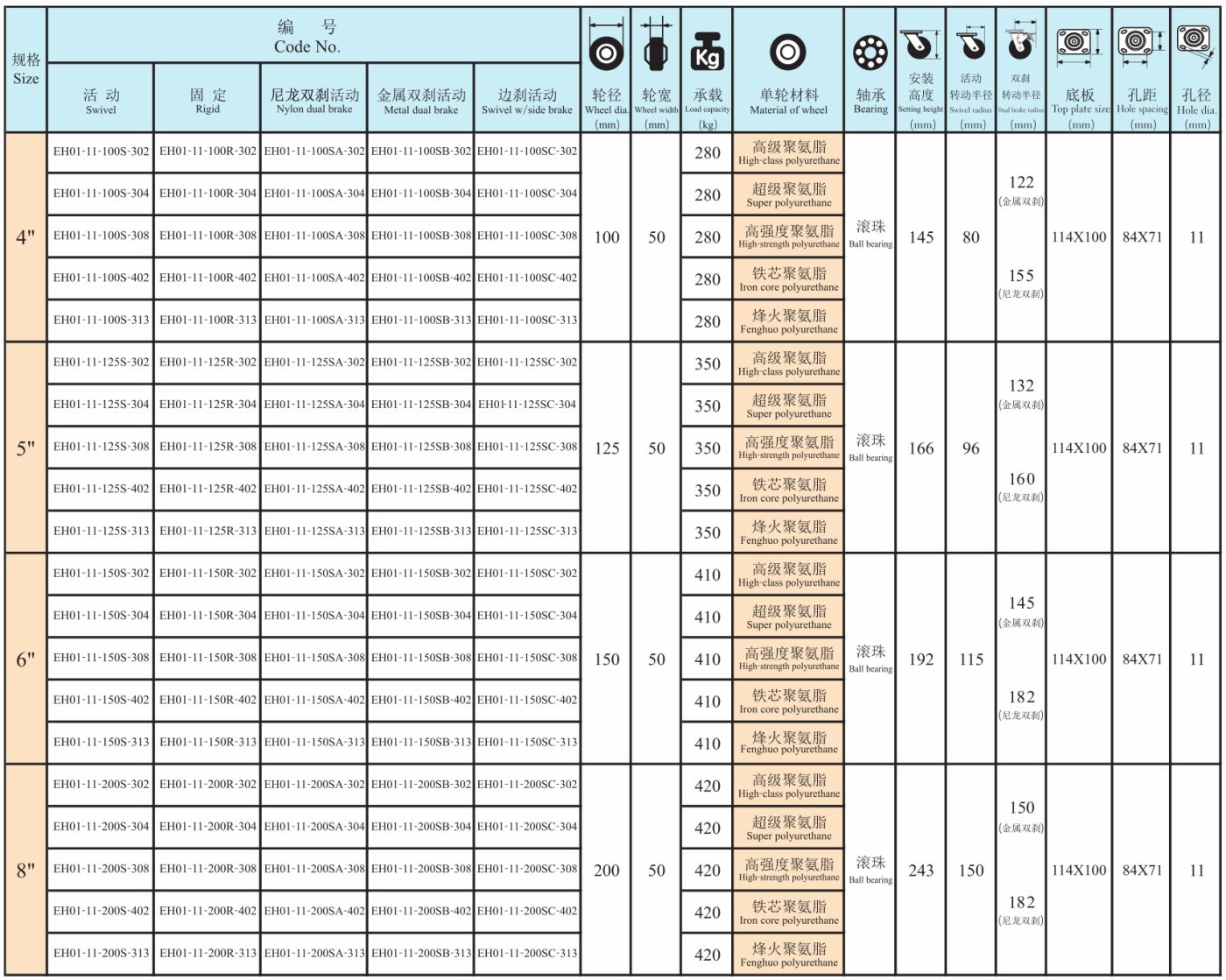

Bottom price Cabinet Castor - EH1 Series -Top plate type-Swivel/Rigid(Zinc-plating) – GLOBE

Bottom price Cabinet Castor - EH1 Series -Top plate type-Swivel/Rigid(Zinc-plating) – GLOBE Detail:

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

Advantages of heavy duty casters

Heavy-duty casters are a kind of caster products with a relatively large load. Generally speaking, its specifications are from 4 inches to 12 inches, and the carrying capacity is 1 ton -10 tons or higher. The thickness of the bracket can be selected from 8mm, 10mm, 16mm, 20mm. It is made of steel plate or cast, and the single leg is made of rubber, nylon, polyurethane as raw materials, which can be used in different environments. The surface of the caster bracket is treated with anti-corrosion, which is durable, flexible and easy to use.

Casters are required for many tools and are a very convenient accessory. Let us take a look at the advantages of heavy casters:

1. Heavy-duty casters include heavy-duty nylon casters, heavy-duty rubber casters, heavy-duty cast iron casters, and heavy-duty polyurethane casters, all of which are made of 12-20 mm thick steel plate stamping or direct casting, suitable for short-distance movement of 500-10000 kilograms. Various heavy duty casters can be customized according to the size and material required by customers.

2. Heavy-duty casters use pressure bearings, roller bearings and ball bearings.

3. Casters of different materials (nylon, polyurethane, cast iron, rubber) can be selected according to different environments.

4. Heavy-duty casters have large bearing capacity and are sturdy and durable.

5. The wheel frame adopts two different treatment methods, which can be selected according to the conditions of use. (Plastic spraying and galvanizing)

Product detail pictures:

Related Product Guide:

To be the stage of realizing dreams of our employees! To build a happier, more united and more professional team! To reach a mutual benefit of our customers, suppliers, the society and ourselves for Bottom price Cabinet Castor - EH1 Series -Top plate type-Swivel/Rigid(Zinc-plating) – GLOBE , The product will supply to all over the world, such as: Lithuania, Paraguay, Bangladesh, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our goods. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for you personally always.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly