2022 Latest Design Locking Caster - Bolt hole Swivel/Swivel Brake Flat PU Industrial Caster Wheel – GLOBE

2022 Latest Design Locking Caster - Bolt hole Swivel/Swivel Brake Flat PU Industrial Caster Wheel – GLOBE Detail:

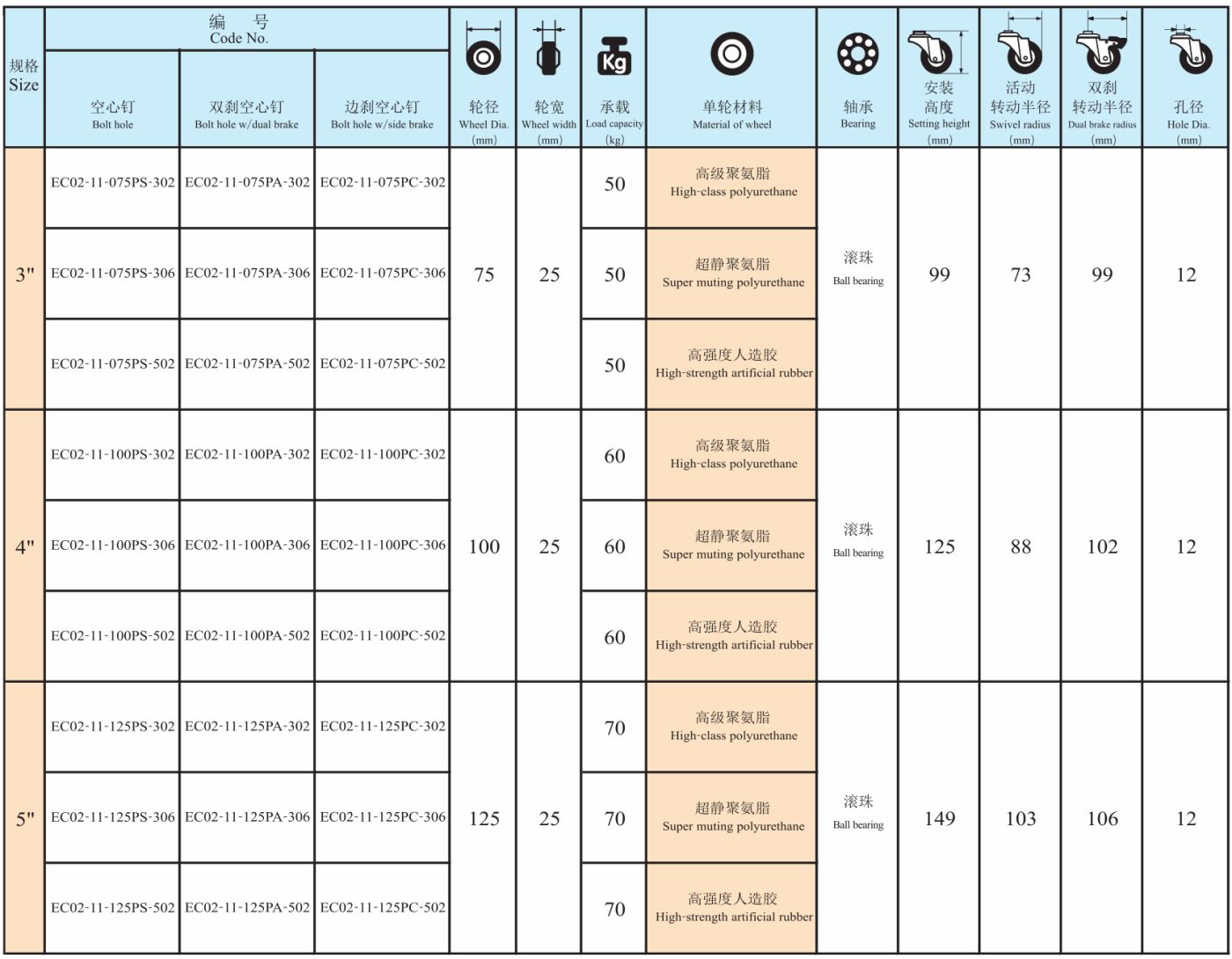

High-class PU caster

Super muting PU caster

High-strength artificial rubber caster

Advantages on our products:

1. High quality materials purchased with strictly quality check.

2. Each product checked strictly before packing.

3. We are professional manufacturer for over 25 years.

4. Trial order or mixed orders are accepted.

5. OEM orders are welcome.

6. Prompt delivery.

7) Any type of casters and wheels can be customized.

Contact Us Today

We adopted advanced technology, equipment and high-quality materials to ensure the flexibility, convenience and durability of our products. In different circumstances, our products have wear, collision, chemical corrosion, low/high temperature resistance, trackless, floor protection and low noise features.

Testing

Workshop

How to distinguish the quality of medium casters

1. From the appearance of the support frame of the medium-sized caster, the thick steel plate support frame of the medium-sized caster has a beautiful surface, no burrs, and the thickness must be symmetrical, and then the quality of the load is ensured;

2. Hot-dip galvanized support frame for medium-sized casters In order to prevent corrosion, hot-dip galvanizing processing technology is generally used. Inquire about the hot-dip galvanized support frame of medium-sized casters should be uniform and glossy;

3. The electric welding of the electric welding of the medium-sized caster support frame and the electric welding of the thick steel plate should be smooth, and there is no need for welding, leakage, etc.;

4. Standards for common wheels of medium-sized casters;

5. Query the surface layer of the medium-sized casters to be moisturized, without scratches, with well-proportioned color, and no significant color cast;

6. Query the overall effect of universal medium casters. When the cast-in-place slab rotates, every rigid ball should be able to touch the changing surface of the thick steel plate. The bearing capacity should be well-proportioned, and the rotation should be dexterous without significant interruption;

7. Inquire about the application of medium-sized casters. Rolling bearing quality. The medium-sized casters do not need to have significant vibration when they roll over.

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product Quality, Reasonable Value and Efficient Service" for 2022 Latest Design Locking Caster - Bolt hole Swivel/Swivel Brake Flat PU Industrial Caster Wheel – GLOBE , The product will supply to all over the world, such as: UK, Gambia, Czech, To meet the requirements of individual customers for each bit more perfect service and stable quality products. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!